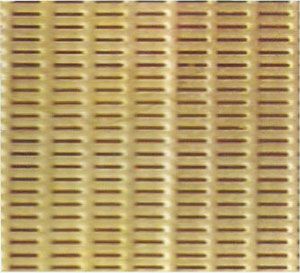

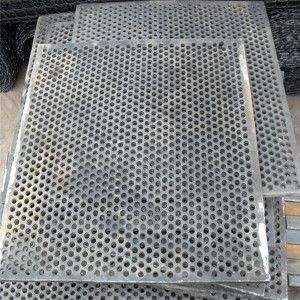

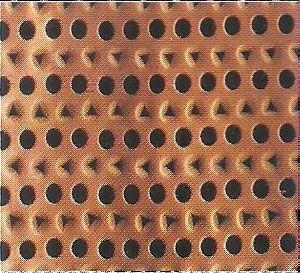

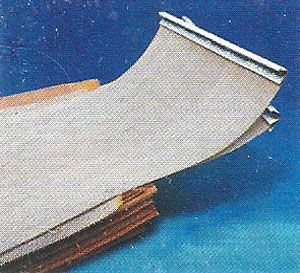

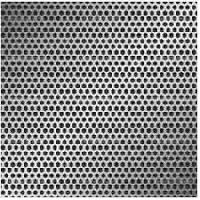

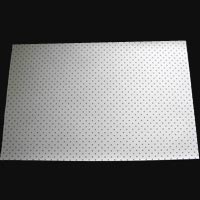

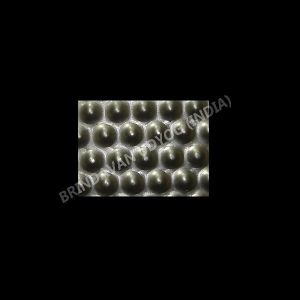

We ensure that the delivery schedule should be properly maintained in order to meet the exact requirements of the customers. Due to our streamlined packaging system, we are able to meet standard as well as tailored packaging requirements of the patrons. Also, we guarantee complete safety of the products. Product Range of Centrifugal Screens : Working Screens : Having Conical Round Holes & Elongated Taper Slot in copper , Brass and S.S Metals and steepcone Basket Screens duly welded & silver Brazed with jointing Strips. Supporting/Backing Pattern : Wire Nettings , Plain & Dovex type Triangular stabbed with Round Hole, Stabbed Hole , Perforated & Corrugated in All Metals. Others : Sugar Grader Mesh , Mogensen Screens , Nickel Screens, DSM Screens, Bagacilo Screens Important Suggestions : All Screens for Centrifugal Machines Manufacture of costly metals , variation of thikness direct effects its pricing , consumption, durability, labour cost & economy of Sugar Mills. To avoid this pilferage and procurement of quality screens consider our suggestions as under : Prefer to purchase copper/brass screens at rate per K.G basis instead of per piece and verify thickness from weight chart. For durability and better results brass screens should be 63cu : 37zn and copper screens should be 99.9 purity. Stenless Steel Screens should be of 304 grades as specified in vaccum filter screens specification on back page.