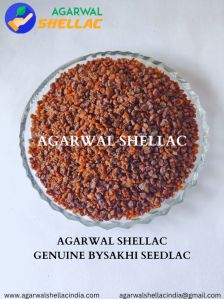

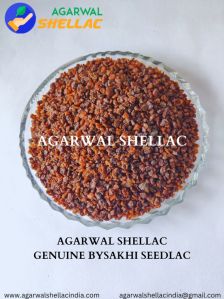

Despite the removal of much of the red dye from the lac seeds in the refining process, shellac remains an orangish solution after processing is complete. Some consumers prefer a clear shellac finish which can be obtained by bleaching the colour from shellac. Bleaching begins with dissolving the seedlac, which is alkali-soluble, in an aqueous solution of sodium carbonate. The solution is then passed through a fine screen to remove insoluble lac, dirt, twigs, etc. The resin is then bleached with a dilute solution of sodium hypochlorite to the desired color. The shellac is then precipitated from the solution by the addition of dilute sulfuric acid, filtered, and washed with water. It is dried in vacuum driers and ground into a white powder. Application : Shellac Etch Primer(Wash primer)-Effective anti corrosive primer for any metal surface Pharmaceutical industry for coating Capsules, Pills and tablets serves as moisture barrier. Flexographics printing inks-Because of strong adhesion, superior gloss, abrasion resistance Grinding wheels-It is binder for additive of grinding wheels Cosmetics-Hairs lacquers. sampoos and sprays. Antique frames for paintings Paints-Primer for Plastic parts and plastic films Confectioneries-For coating chocolate goods as it enhances and protects the gloss extends shelf life and serves as a barrier to moisture either entering or leaving the confections. Paper Varnishes-Playing Cards Leather dressings-produces flexible waterproof, glossy finish. Coating of coffee beans. In textiles --used in textile auxilliaries, felt hat stiffening agents. Vegetable/food coating of oranges, lemons, apples, avocados, plants tomatoes, dry flowers etc. Electric (it is binder for lamp cements). Electronics (it is binder for insulation materials, serves as additive to moulding compounds. Mass coating for print-plates and is adhesive for si-cells.)