Welcome to SAKTHI SUGARS LIMITED

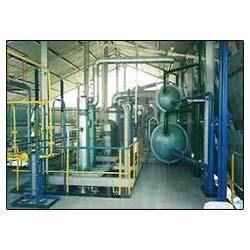

Manufacturer / Exporter / Supplier / Retailer Of Solvent Extraction Plant, Soya Fatty Acid, Defatted Soya Flour, Refined Soybean Oil, Soya Grits

Welcome to SAKTHI SUGARS LIMITED

Manufacturer / Exporter / Supplier / Retailer Of Solvent Extraction Plant, Soya Fatty Acid, Defatted Soya Flour, Refined Soybean Oil, Soya Grits

The soap stock obtained during neutralization of soybean oil is collected in an acid proof vessel and acidified at an elevated temperature. The acidification results separation of fatty matter from the soap-water-oil mixture. The fatty matter is collected separately as acid oil and stored in the storage tank.

Toasted Defatted Soya Flour is the enzyme inactive soya flour manufactured by using only highest quality soybean seed as the starting material. These are cleaned twice to remove all foreign material. After cleaning the beans are conditioned, cracked, de-hulled and rolled into flakes. The flakes are conditioned to a solvent bath that extracts the oil. After highly efficient extraction it is de-solventised and toasted to required PDI level and ground to ultra-fine quality through the ACM and sieved through Vibro meshes.

The solvent extracted crude oil is treated with water at an elevated temperature that causes the swelling of phosphorus-containing oil in gum form. This gum is separated by high speed centrifuging separators. To neutralize the free fatty acids, caustic treatment is given and the neutralized oil is again separated by high speed centrifuging separators. The neutralized oil is bleached and filtered by use of activated earth. To remove the odour present in oil, it is heated at high temperature followed by suction and condensation of low b.p. fatty acids. The finished oil is stored in storage tanks.

These are the enzyme active soya flour manufactured by using only the highest quality soybean seed as starting material. These are cleaned twice to remove all foreign material. After cleaning the beans are conditioned, cracked, de-hulled and rolled into flakes. The flakes are treated to a solvent bath that extracts the oil. After highly efficient extraction they are desolventised through Flash Desolventising System without denaturing the protein, thereby maintaining high PDI value. The desired consistency of the product is obtained through the Vibro grader.

It has a capacity to crush 350 MT soybean seeds per day. The flash de-solventising system de-solventises the spent soybean flakes in a couple of seconds thereby retaining the enzyme activities with minimal protein denature.

Share your thoughts with other customers for SAKTHI SUGARS LIMITED

Add Review