Listing ID #3852372

Company Information

Ask for more detail from the seller

Contact Supplier|

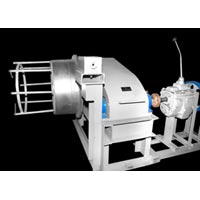

Wire Condenser Welding Machines Salient Features: High Speed of Operation: Lower Current demand: Accuracy of Set down: Uniform Welding Quality: Lesser consumption of Electrodes: Lower maintenance: Operation & sequence: Machine control: The welding is controlled through mechelonic enginerrs make 400 series microprocessor based welding controller with constant current facility thus providing consistent welding quality. The controller has a in built facility for line voltage compensation for fluctuating line voltage |

|

Note :: Machine is normally provided with three welding heads & one 75 KVA transformers, If any particular requirement for 4 welding heads & more than one welding transformers is felt the same can be given. Also as a standerd single phase AC transformer is give, but un option of 3 phase DC transformer is also available. |