Listing ID #4073296

Company Information

Ask for more detail from the seller

Contact SupplierRequests for cleaning processes in the wire industry are continuously increasing and at the same time with increased quality requirements. Cleaning is the removal of contaminants present on the surface of the wire but not.chemically.linked.to.it.

Cleaning is used for stainless steel, low and high carbon steel, aluminum alloy, copper wire to remove calcium and sodium parts lubricant residues after the dry drawing process, or lubricant oil from a wet drawing machine or forming process etc.

Two types of technologies are usually proposed for this purpose: ultrasonic cleaning and electrolytic cleaning. Both of them have advantages and have to be chosen carefully depending on the type of wire and the type of products to be removed from the wire. Let’s compare briefly the two technologies.

Ultrasonic cleaning is the use of high frequency sound waves. This results in cavitation, in which micro-size bubbles form, grow and implode due to alternating positive and negative pressure waves. Just prior to the bubble implosion, there is a tremendous amount of energy stored inside the bubble itself. The implosion event if it occurs near a hard surface changes the bubble into a jet which travels at a speed of approximately 400km/h towards the hard surface. Because of the inherent small size of the jet, ultrasonic cleaning has the ability to reach into small crevices.and.removed.entrapped.soils.very.effectively.

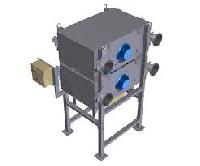

The basic components of an ultrasonic cleaning system include some ultrasonic transducers, an electrical generator.and.a.tank.containing.the.cleaning.solution.

The ultrasonic generator converts a standard electrical frequency of 50 or 60 Hz into the high frequencies required. The higher the frequency, the smaller the bubbles created during the cavitation will be.

The transducers are constituted of PZT elements (Pb-Zr-Ti) which converts the electrical energy into mechanical vibrations by piezoelectric action. The transducers are installed inside a watertight box made in stainless steel immersed in the cleaning bath and located some centimeters below the wire field. A watertight cable connects the transducer holding box to the generator.

The cleaning solutions used in the ultrasonic cleaning lines have to be chosen with care taking consideration of the type of wire and the application. Generally speaking for the majority of the applications in the wire industry, alkaline solutions are preferred to remove oily matter and phosphoric acid

based solutions are preferred to remove stearate soaps.

The working temperature has a profound effect on ultrasonic cleaning effectiveness. In general higher temperatures will result in higher cavitation intensity and better cleaning. However, if the solution temperature too closely approaches the boiling point of the solution, the liquid will boil in the negative pressure areas of the sound waves, reducing or eliminating the cavitation effect. We usually work around 60°C (140°F) which offers an excellent compromise.

In the electrolytic process, the wire passes through an electrolyte in a processing zone divided into different chambers. Electrodes are located in each chamber and adjacent electrodes are connected to opposite poles of a direct current supply source. Electrical current is constantly passing between the electrodes in the adjacent chambers through the electrolyte and the wire while it is traveling through the chambers in the processing zone. In this way, the wire is alternately polarized negatively and positively as it travel through the processing zones. The migration of ions of the electrolyte as a result of the polarization will allow some chemical reactions to take place quickly at the surface of the wire like hydrogen or oxygen bubbles formation. Those bubbles created at the surface of the wire will remove by a mechanical effect the dirt present on the wire.