Listing ID #3407956

Company Information

Ask for more detail from the seller

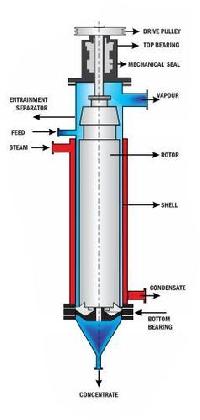

Contact SupplierThe operation process in the WFE is simple but yet effective. Feed is introduced at the top of the unit and spread on the shell inner surface by the rotating distribution plate. Specially designed wipers wipe the feed thus creating and renewing the film. This thin film enables an efficient heat transfer even for highly viscous fluids. The low boiling component evaporates and passes through an entrainment separator. This minimizes the carry over of liquid droplets along with the vapors. The vapors are removed through the vapor line to an external condenser (optional) and condensed. For specific applications which demand low pressure drop, the central section of the evaporator is provided with a condenser, thus making the unit a short pathmolecular distillation unit. In this case, the vapors are allowed to condense on the outside of the tube bundle and flow out of the vaporator via the condensate outlet provided at the centre.

The high boiling component flows along the shell wall and is discharged from the product outlet. Wiper action is important in promoting downward flow. The productconcentrate should be in fluid form at the operating temperature. Different designs of rotors are available depending upon the product, its viscosity and the process pressure.