Listing ID #1163352

Company Information

Ask for more detail from the seller

Contact SupplierWe Offer Wet- Scrubber for Boiler.

If you wish to remove the particulates (and or droplets) from a corrosive gas stream, there is a SGEW Umbrella Scrubber system will give you collection efficiencies in excess of 99% with water, and this for a relatively low capital outlay.

It is made up of S.S. 316 and thickness as per required by client. This scrubber is made on the theory of Cyclone i.e. in this scrubber we use high velocity of cyclonic force and this force is shuttle down the maximum particles in to boiler out-let flue gas. We use the baffle plate for reduce the velocity of gas for better scribing on this we give water spray from above as well as from bottom. We used spiral (umbrella) nozzle in this scrubber to give the form of like umbrella.

Cyclone separators provide a method of removing particulate matter from air streams at low cost and low maintenance. In general, a cyclone consists of an upper cylindrical part referred to as the barrel and a lower conical part referred to as cone. The air stream enters tangentially at the top of the barrel and travels downward into the cone forming an outer vortex. The increasing air velocity in the outer vortex results in a centrifugal force on the particles separating them from the air stream. When the air reaches the bottom of the cone, an inner vortex is created reversing direction and exiting out the top as clean air while the particulates fall into the dust collection chamber attached to the bottom of the cyclone.

FRACTIONAL EFFICIENCY CURVE

The cyclone fractional efficiency curve (FEC) relates percent efficiency to the particle diameter and can be obtained from test data that include inlet and outlet concentrations and particle size distribution (PSD�s). It is commonly assumed that the FEC can be defined by a cumulative lognormal distribution. As a lognormal distribution curve, the cyclone FEC can be characterized by the cut-point (d50) and sharpness-of-cut (the slope of the FEC) of the cyclone. As mentioned above, the cut-point of a cyclone is �Automatic Entry Device (AED) and Cyclonic action help to remove particles with 50% efficiency of Dry Gases. Remaining particles are removed with the help umbrella nozzles, and deflector.

In this scrubber there is two cleaning door and a baffle plate and a spiral nozzle. It is in the cyclonic form at high velocity and it is broken from centrifugal force.

Design Features of the Scrubber:

The scrubber is equipped with a Special Umbrella Nozzle placed in the Centre.

This scrubber is developed to work for almost all type of fuel burning system.

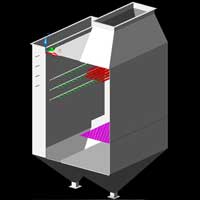

Scrubber is designed in Five parts

1. Centre Entry of Hot Flue Gas

2. Gas passing with cyclonic movement over Umbrella Spray

3. Bottom Water seal compartment

4. Baffle and Flow deflector

5. Mist eliminator Each parts are designed with most care for functioning to its maximum efficiency and with collective efficiency to give best scrubber effect for almost any type of gas exhaust.

Care has been taken in every stage to give maximum scrubber efficiency.

This further improves performance and overcome the design limitations of the existing scrubbers.

a. The New �Umbrella scrubber � work with less water consumption

b. Nozzle chocking problem has been minimized

c. Umbrella nozzle cleaning arrangement is easy and replacement of nozzle is easier.

d. Back wash cleaning arrangement of nozzles with periodic time interval.

e. Steam injection helps to clean mist eliminator during working.

f. All the material is of Stain less steel 316 quality with appropriate thickness

g. The Hot flue entry with special Entry design ensures the minimum erosion of material.

h. Upper compartment design with deflector and mist eliminator improves the absorption of the Sulphar gas and other gases.

i. Umbrella Scrubber designed efficiency near to 99 % with water.

AirPol- Strip Buffle Cyclomax Scrubber

The contaminated gas is brought into intimate contact with curtains of liquid spray directed at right angles to the gas flow after it enters the involute section. The scrubbed gases proceed along the involute where the bulk of the liquid is separated. The remainder of entrained droplets is removed when the accelerated gases enter the spin zone. The liquid moves by gravity to the bottom cone drain, and the cleaned gases leave the scrubber at the top outlet.

How it works....

AirPol- Strip Buffle Cyclomax Scrubber

...and the advantages

* Higher efficiency due to Involute Gas Inlet - concentrated spray zone

Assures more efficient scrubbing than the conventional cyclonic design

*Low equipment costs because of reduced height � positive entrainment separation in involute section reduces scrubber height and space requirements

*Trouble-free operation as there are no internals - no internal baffles, plates or vanes to separate entrained droplets from gas stream; Scrubber creates positive centrifugal action to spin droplets from gas

*Minimal maintenance because of wall mounted sprays � wall mounting of large orifice non-clogging nozzles offer trouble free operation. Spray nozzles have individual shut off valves for servicing without interruption of scrubber operation *Low pressure drop design - typically operates at 75 to 150 mm WG

Typical Applications: -

*Bagasse and other bio-mass fired boilers

* Fertilizer plants

* Woodworking operations

* Driers and coolers

* Rock products operations

* Non-ferrous metals processing

* Pulp and paper processing sewage sludge (incineration)

* Pelletizing - crushing and screening

Capture Mechanisms:-

Particulates contact liquid droplets in wet scrubbers through several mechanisms. Impaction is the primary capture mechanism. When waste gas approaches a water droplet, it flows along streamlines around the droplet. Particles with sufficient inertial force maintain their forward trajectory and impact the droplet. Due to their mass, particles with diameters greater than 10 �µm are generally collected using impaction [3]. Turbulent flow enhances capture by impaction. Particles dominated by fluid drag forces follow the streamlines of the waste gas. However, particles that pass sufficiently close to a water droplet are captured by interception, capture due to the surface tension of the water droplet. Particles of roughly 1.0 to 0.1 �µm in diameter are subject to interception [21]. Increasing the density of droplets in a spray increases interception [1].Very small-sized particles are subject to Brownian motion, irregular motion caused by random collisions with gas molecules. These particles are captured by the water droplet as they diffuse through the waste gas. Collection due to diffusion is most significant for particles less than 0.5 �µm in diameter [1]. Capture mechanisms that are used less frequently include condensation and electrostatics. In condensation scrubbing, a gas stream is saturated with water vapor and the particle is captured when the water condenses on the particle [3]. In electrostatic scrubbing, contact is enhanced by

placing an electrostatic charge on the particle, droplet, or both [2].

Duel Shell Wet Scrubber:-

LIQUID-TO-GAS RATIO (LG ratio)

An important parameter in wet scrubbing systems is the rate of liquid flow. It is common in wet scrubber terminology to express the liquid flow as a function of the gas flow rate that is being treated. This is commonly called the liquid-to-gas ratio and uses the units of gallons per 1,000 actual cubic feet or literscubic meter (lm�³).

Expressing the amount of liquid used as a ratio enables systems of different sizes to be readily compared. For particulate removal, the liquid-to-gas ratio is a function of the mechanical design of the system; while for gas absorption this ratio gives an indication of the difficulty of removing a pollutant. Most wet scrubbers used for particulate control operate with liquid-to-gas ratios in the range of 4 to 20 gallons per 1,000 actual ft�³ (0.5 to 3 liters per actual m�³).

Assurance:-

We have assure you, we give 100% guarantee about our machine is make for pollution control as per the norm & conditions of GPCB & CPCB.