Listing ID #270299

Company Information

Ask for more detail from the seller

Contact Supplier|

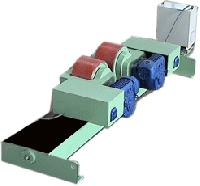

We manufacture high quality rotators which are being used with various processes such as SAW/ TIG/ MIG/ ARC/ etc., capacities upto 2000 Tons. Steel rollers or polyurathene lined rollers are provided as per application. For higher capacity rotators forged rollers are provided.

• Our Standard Rotators consists of drive and idler unit. The frame and roller brackets are fabricated with heavy sections, relieved and precision machined. • Overload disc to protect polyurethane roller. • Steplessely variable surface speed from 75 to 1500 mm/min.or higher and controlled through AC Variable frequency drives. For precision movement encoder feedbacks are provided on case basis. • Forward/ reserve rotation and emergency stop facility on panel. • Operator pendant with forward/ reverse inch or run speed variation and stop functions. |

|

|

|

|

|

Application

|

|

|

Welding of Pipes, API pipes, Boilers, Heat Exchangers, Pressure Vessels, Mounted Vessels, LPG ullets, Barrels, Tanks etc.

|

|

|

Advantages

|

|

|

• An indispensable tool for shell fabrication shops.

• Attains exceptional quality circumferential joints on shells. • Increased production with reduced labour skill. • Leads to minimum Shell/ Job handling. • lesser usage of crane reduces idle time. • Improves plant efficiency. • Welding automation. |