Listing ID #270303

Company Information

Ask for more detail from the seller

Contact Supplier|

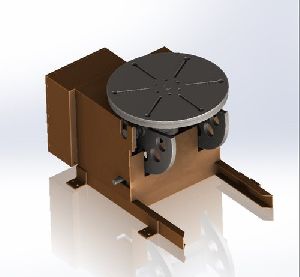

welding positioners aligns the job to the best position for down hand welding for non circular jobs or for rotating circular jobs.

|

|||||||||

| features : | |||||||||

|

• light duty series

• ideally suitable for small jobs in the range of 50kg to 150kg. • designed to give accurate and controlled movement. • job can be tilted any side for convenient operation. • face plate rotates with variable speed. • available with optional accessories like torch stand, foot switch & operator pendant etc. medium & heavy duty series : covers wide range of jobs starting from 250kgs to 250 tons. Designed and manufactured for trouble free and easy operation. |

|

||||||||

|

fabricated with heavy sections which avoids deflection under loaded conditions resulting in vibration free and smooth operation. Anti-fall arrangement for face plates gives additional safety. Positive locking for tilting arrangement with instant braking arrangement ensures safety and accurate positioning. Rotary drive unit with ac variable frequency drive (vfd) provides steplessely variable speed from 0.1 to 1 rpm for face plate. Earthing arrangement with wear compensation gives uninterrupted welding as well as safety to the positioner elements. Tilting arrangement from 0 to 135 degrees ensures approach to all joints.

|

|||||||||

|

main advantages

|

|||||||||

|

• easy positioning of odd shaped jobs for downhand welding.

• allows maximum flexibility in job handling. • with minimum handling. Maximum accessibility to joint is assured. • eliminates frequent usage of crane, reducing idle time. • increased production with reduced labour. • single handed job manipulation and welding reduces labour cost. • improved weld quality (even with unskilled operator) reduces weld defects and rejection. • adaptable for automatic of manual welding. • convenient for assembling intricate sub-assemblies. • ideal for in conjunction with column & boom. |

|||||||||

|

special features of our design

|

|||||||||

|

|||||||||