Listing ID #4487950

Company Information

Ask for more detail from the seller

Contact SupplierSpecifications

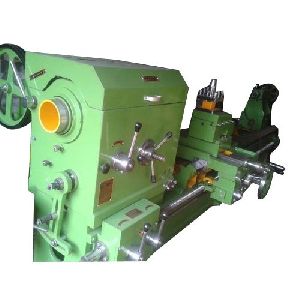

Manufacturers of Automated Welding Lathes

Plasma Welding Lathe

The Arcraft Plasma Welding Lathe has been innovatively engineered to provide a versatile platform for high production circumferential welding applications with superior accurate and repeatable results .

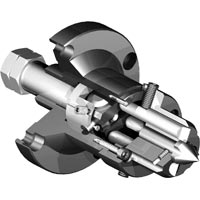

You can use GTAW ( TIG ) , PAW ( Plasma welding ) , MIG & FCAW process whether used for simple or complex components . The system consists of a/c geared headstock designed to accommodate a chuck , faceplate or any required fixture , an adjustable weld head mounting post that rides on a precision base and a pneumatic cylinder operated tailstock.

The Headstock rotation & the welding process sequencing are controlled by microprocessor control.

The control panel has digital screen with simple touch pad controls

Special Features

1. Accurate motorized Spindle with through bore 2.85” diameter

2. A/C Geared motor driven Headstock with 0.5 to 5 rpm speed range ( higher or lower speeds available on request

3. Precision fabricated MS lathe bed

4. 12” (305 mm) diameter part swing . Larger capacity available on request.

5. 18” (455mm) part length capacity Plasma Welding Lathe

The Arcraft Plasma Welding Lathe has been innovatively engineered to provide a versatile platform for high production circumferential welding applications with superior accurate and repeatable results .

You can use GTAW ( TIG ) , PAW ( Plasma welding ) , MIG & FCAW process whether used for simple or complex components . The system consists of a/c geared headstock designed to accommodate a chuck , faceplate or any required fixture , an adjustable weld head mounting post that rides on a precision base and a pneumatic cylinder operated tailstock.

The Headstock rotation & the welding process sequencing are controlled by microprocessor control.

The control panel has digital screen with simple touch pad controls

Special Features

1. Accurate motorized Spindle with through bore 2.85” diameter

2. A/C Geared motor driven Headstock with 0.5 to 5 rpm speed range ( higher or lower speeds available on request

3. Precision fabricated MS lathe bed

4. 12” (305 mm) diameter part swing . Larger capacity available on request.

5. 18” (455mm) part length capacity

6. Manually adjustable tailstock & torch mast including torch swivel

7. Part weight capacity of 250 lb ( 113 kg)

8. Mounting flange on headstock to accept optional tooling

9. 200A welding ground

10. Pneumatic lever operated tail stock with retract 2” stroke

11. Cold wire feeder available.

Optional

1. Arc voltage controls (AVC)

2. Servo driven wire feeder

3. Motorized torch mast for linear welding applications

4. Pneumatic torch retractors sequenced by the system controller

5. Synchronised arc length control, cold wire feeder & magnetic arc control systems

We provide welding process integration & weld testing of your jobs as per

International Codes.

Custom designed lathes and supporting automation can be designed and manufactured as per the job requirement.

6. Manually adjustable tailstock & torch mast including torch swivel

7. Part weight capacity of 250 lb ( 113 kg)

8. Mounting flange on headstock to accept optional tooling

9. 200A welding ground

10. Pneumatic lever operated tail stock with retract 2” stroke

11. Cold wire feeder available.

Optional

1. Arc voltage controls (AVC)

2. Servo driven wire feeder

3. Motorized torch mast for linear welding applications

4. Pneumatic torch retractors sequenced by the system controller

5. Synchronised arc length control, cold wire feeder & magnetic arc control systems

We provide welding process integration & weld testing of your jobs as per

International Codes.

Custom designed lathes and supporting automation can be designed and manufactured as per the job requirement.