Listing ID #3739242

Company Information

Ask for more detail from the seller

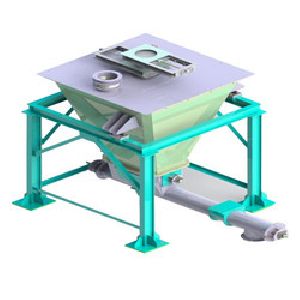

Contact Suppliersweipl, in collaboration with saet, italy offers weigh feeders to feed bulk solids continuously to the process . The weigh feeders –dprc & dpn are suitable for installation directly under the silos in industrialized environment with light & heavy duty conditions respectively. The former has been designed to handle small size granulated material whereas the latter can cater to a complete range of material size.

high quality measurement and control electronics allow both convenient operation and extensive monitoring, assuring high accuracies of feed. Belt weigh feeders are able to control in continuous mode, the flow of the discharged material maintaining the instantaneous flow rate constant with respect to the set rate. The weight is measured directly at the weighing zone sensed by a centrally placed weighing idler which is placed on two numbers of high precision, international class load cells having high resolution strain gauges of minimum displacement (0.1mm). A digital tachometer detector generates the signal in proportion to the speed of the belt.the device is supplied complete with a command and control cubicle, equipped with our electronic weighing system ws200/d series.

the belt load and speed signals are routed through the microprocessor based weighing and feeding controller, where they are processed and an actual feed rate is continuously compared with the set rate (set point) to assure that the belt speed is controlled such that the feed rate is maintained at a constant level throughout. Precision attained is superior to ±0.5% of the set flow rate. The weighing systems compensate the apparent density variation within a range of ±30%. The supporting structure of the weigh feeders may be so designed to be an integral part of the fairing that encloses the machines. As this guarantees completely dust tight protection so pressure proofing, if needed, is possible.

the closed ring vulcanized rubber belt can be easily replaced without requiring the disassembly of the machine components. Automatic belt tracking prevents disruption to process by belt running askew. Belt drift, if any, is monitored with the aid of opposite limit switches.

gravity take ups assure constant but tension preventing belt slippage & overworking.to improve performance a speed sensor is installed at tail pulley to detect belt slippage if any. Two prevent belt contamination and tare changes an adjustable scrapper outside the belt, while a plough defector inside the belt has been used as a suitable design for belt cleaning system. The plough deflector prevents belt destruction due to foreign objects jammed between belt and pulley. Available on request are sundry solutions with the use of scrapes, collecting screw feeders, hoe scrapers.

options:

1. Fairing

2. Special scrapper

3. Feeding hopper

4. Conveyor belt with containment edges

5. Second weighing bridge (for dpn only)

6. Prefeeders – feed hopper, star feeder, shaker etc (for dpn only)

for each bulk material the right feed hopper /prefeeder

feed hopper for free-flowing material

vibrating hopper for sluggish materials

starfeeder for flushing materials

feed gate for fluidized materials