Listing ID #3915151

Company Information

Ask for more detail from the seller

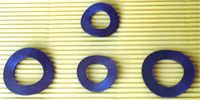

Contact SupplierSpring Steel & Stainless Steel in 2 / 3 / 4 waves, gap type, overlap type, double wave type

A wave spring is made from coiled flat wire with waves added to give it a spring effect. The on-edge-coiling process creates a circle with one or more turns to specifications in any diameter and any number of specific designed waves. When compared with typical coil springs, wave springs have equal performance with about half of the overall free height. This not only provides for space savings, but also smaller assemblies that use less materials, hence lower production costs. Wave springs are a precision spring and available in many styles and materials.

Wave Washers are solid washers that have pressed waves. These items are typically used to offer preload to bearings and bolts

Flat Wire Wave Springs v/s Conventional Stampings

Applications: