Listing ID #3903006

Company Information

Ask for more detail from the seller

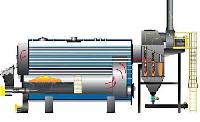

Contact SupplierRevosteam is a unique water tube coil type boilerin which water flows inside the tube. Revosteam is mostly oil-fired or gas fired boilers which include burner assembly to fire oil or gas.

It incorporates the unique principle of combustion known as “Reverse Flow”. Reverse flow means that flue gas reverses its path when they hit the bottom of the shell. This flow of flue gases enhances the combustion efficiency and also allows a high rate of heat release to the surrounding water coil. It can be offered in both IBR and Non-IBR designs

Revosteam Construction

A Water tube Coil type boilercomprises a jacketed MS shell housing a helical coil. The combustion air is forced through the jacketed shell by means of a centrifugal blower thereby getting it pre-heated. For the Revosteam Boilers, in the coil, the flame travels downwards 1st because of vertical fit-up of the burner inside the coil then the flue gases reverse upwards in the same coil thereby giving 2 passes in the same radiant zone. This ensures maximum radiation heat transfer to water through tubes. After reversing its path, flue gases reach the top of the shell and from there, the flue gases pass between the inner shell and the coil which makes the 3rd pass of flue gases. The high velocity of gases in this region allows heat exchange between the gases and water through convective heat transfer. After completing 3 passes in the boiler, flue gases then enter the economiser. Economiser which is kept on the same skid as a boiler is a shell and tube design. In this flue gases are on the tube side while water is on the shell side. Economiser is generally given to pre-heat water entering the boiler. Along with other accessories optimiser is also installed on a skid in series with the boiler and an economizer so as to maintain the inlet water temperature to the boiler. The inner shell separates the flue gases & outer shell. Ceramic blanket is applied on the inner side of the outer shell to reduce the heat transfer to the ambient and the surface temperature of the outer shell in the Revosteam Boiler.

Advantages:

Capacity:-

Revosteam- Water Tube Coil Type Boiler is available in capacities from 1 hundred Kg/hr to 12 hundred Kg/hr.

We, at Thermodyne engineering Systems, design and manufacture the Revosteam Boilers for both Liquid/Gas Fired Fuels. And the best part is that complete fit-up of mountings, fittings and accessories is checked, inspected which is further followed by a test run of the Boilerto ensure maximum customer satisfaction during future boiler operation.