Listing ID #414763

Company Information

Ask for more detail from the seller

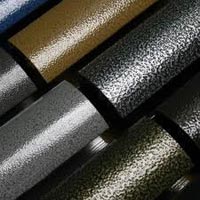

Contact SupplierThe building construction materials are mostly mineral based and they have high porous surface structure which readily absorbs water. The exterior facade get damaged and discolored by rain and atmospheric pollutants. The latest advancement in construction industry is the use of insulating masonry and lightweight blocks and plasters which retain water and moisture. Any absorbed moisture must be able to escape to the atmosphere to protect interiors. To overcome these problems there is need of a coating which must have very high water - vapor permeability, low water absorption, attractive decorative appearance and extreme durability. The Water Dilutable Epoxy Coatings, offered by us, meet all these requirements with mineral like matt finish. Clients can avail from us Water Dilutable Epoxy Coatings of the well-known Hydraepoxy Brand. We make available Water Dilutable Epoxy Coatings at the most competitive prices to the clients.

Benefits| Appearance Part A | Off white, homogenous viscous free flowing paste Off white, homogenous, highly viscous thixotropic paste |

|---|---|

| Mixing Ratio, pbwt | Part A: PartB : water |

| Viscosity of the mix | Free flowing brushable paste |

| Pot life at 25° C, hours surface dry time at 25°c | 1 TO 1-1/2 |

| Surface dry time at 25°C, hours | 4 - 5 |

| Re-coatability time at 25°C hours | 6 - 8 |

| Hard dry time at 25°C, hours | 24 |

| Colour and appearance of the cured film | Semigloss, off white smooth film. |

| Adhesion to damp and dry surface Mechanical properties of film Water , dilute aacid, soap and alcali resistance | Excellent (strong). Hard, tough, scrub and abrasion resistant Excellent. |