Listing ID #4486817

Company Information

Ask for more detail from the seller

Contact SupplierSeparation of solids from solids. Liquids from solids and gradation of materials in accordance with their sizes have always presented problems. Especially when large quantity of material is to be processed through finer screens. In recent times the most important development that took place is the replacement mechanical sifter & vibro sifter in sleving and straining operation. Even if a particle is small it would pass through a screen only if its configuration relating to the opening is favorable.

For a non-isometric particle, the axis must be correctly aligned with respect to the place of the screen and the center of gravity of the particle must be above the aperture at any instant. Further, the amount of material on the screen should be such that passage of small particles is not obstructed by larger particles.

It is therefore necessary to impart horizontal rotary motion to the particle by suitable means. Care also has to be taken to ensure that such motions, particularly during dry sleving or grading operation. should not be vigorous so as to cause size reduction of particles themselves or damage to the screen.

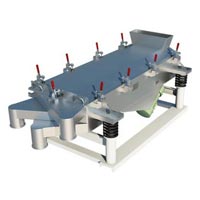

Sieving, Grading and Straining Machine was specially developed with above design features to provide vibration. The amplitude of vibration is adjustable to processing needs.

| Features | Machine on Rubber feet |

| Low charging Height | |

| SS316 contact parts | |

| Options | Double Deck |

| Triple Deck | |

| Four Deck | |

| SS 316 Contact Parts | |

| Silicon coated Sieve. | |

| Lead Free Sieve |