Listing ID #1420082

Company Information

Ask for more detail from the seller

Contact Supplier

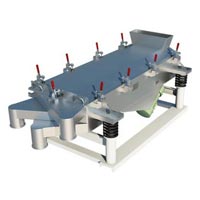

Vibro Sifter works on gyro principle. The required gyratory motion is obtained from specially designed gyro motor, which is fitted underneath the vibrating assembly. The complete vibrating assembly is isolated from the base by means of specially designed rugged springs. Gyro-motor is fitted with top & bottom eccentric weights designed as per required centrifugal force. This whole assembly is covered by SS plate. The deck hopper is fabricated from SS 316 sheet. To collect the discharge tangential, discharge port is provided on the hopper.

Conical shape top lid is provided with charging port. Screen is fitted in between the hopper & top lid. The machine inner & outer surfaces are mirror polished.

CONSTRUTION AND OPERATION :

Vibro separators are circular unitary gyratory screens used to separate mass composition of solids from solids. Liquids from solid and for gradation of materials as per particle size, having a very wide range of applications. This is accomplished by vibrating the screens in three different planes along the vertical axis by means of a specially designed vibratory motor having off centered weights at the top and bottom end of the motor shaft. The top weight causes vibration in the horizontal plane which causes the material to move across the screen towards the periphery. The lower weight acts to tilt the machine which causes vibration in the vertical tangential axis . The angle of lead of the lower weight with relation to the upper weight provides variable control of the screening pattern. Thus the material moves across the screens and also in the vertical and tangential planes enabling maximum screening. Vibrosifter are available with a wide range of possible screen sizes (mesh) option for multiple deck separation is also possible.

The unit consist of specially designed vibratory motor to run on 400/440V , HP, 3 phase, 50 cycles electric supply, with adjustable eccentric weights at the top and bottom of the motor shafts mounted vertically at the center of the base plate of screening unit. Screening unit consists of SS 304 screen sandwiched between SS 304 hopper and bowl with the help of special clamp with gasket. This in turn is clamped to the base plate. Rugged springs placed over the circular motor base amplify the vibration and at the same time restrict the vibration from being transferred to the floor.

SALIENT FEATURES:

Noiseless, Maintenance free & high speeds.

Portable and compact.

Electric power requirement less than other machine of the kind in the industries & lower energy consumption compared to reciprocating vibratory system.

Standard machine are with TEFC motor explosion proof/flame proof motor material.

All contact parts and screen of SS 316 material. & Non Contact Parts in SS 304.

Special requirement like brushing arrangement. SS lid with charging port and spring loaded outlets.

Easy dismantling and cleaning facility for contact parts.

Wide range of screen sizes 4-00 Mesh.

Double & triple deck screens with outlet and hopper for bottom deck available on request..

Amplitude of Vibratory Motion adjustable through moveable eccentric weight.

SS 316 Hood with 200 mm dia Nozzle for dust free charging of Powders.

The machine can easily be dismantled, cleaned & assemble through quick opening SS 316 clamps.

Portable mounted on sturdy Castor Wheels. The Vibrating assembly is isolated by rugged springs.

Finish: Inside - 0.3 Ra. Mirror Polish. Outside - 0.3 Ra. Mirror Polish.

Independent Jacks for lifting the machine off the floor for effective sifting.

Dust free docking station for loading and Unloading.

Silicon Bonded Integrated Mesh.

Silicon Balls for Lump Breaking & Mesh cleaning.

Salient Features :

Design is cGMP - Current Good Manufacturing Practices compliance.

All contact parts AISI 316 & non contact parts AISI 304.

Powerful vibration by gyratory motion by special Vibro motor.

Side outlet & fines discharge.

Easy movable & clean.

Noiseless operation.

Lead free and Silicon seal sieve.

Optional Features :

Inline loading/Milling process and transfer to bin/Blender by Vacuum transfer system.

Double or triple deck sifting system

APPLICATION :

Vibro Sifter is used for screening, sieving, grading for solid-liquid separation, process to separate the desired elements and the undesired elements from the combination of solid to solid (where two solids are generally having different properties) and solid to liquid material.

It used in various industries such as

Pharmaceutical

Chemicals

Cosmetics

Plastics

Paints

Minerals

Rubber Compounds

Metal Powders

Detergents

Pesticides

Fertilizers

Dyestuff

Pigments

| Model |

SFE-VS-20 |

SFE-VS-30 |

SFE-VS-36 |

SFE-VS-48 |

SFE-VS-60 |

|---|---|---|---|---|---|

|

Output- kg / hour |

50 to 200 |

75 to 300 |

100 to 400 |

125 to 500 |

150 to 1000 |

|

Screen Diameter- mm |

500 |

750 |

915 |

1220 |

1524 |

|

Charging height- mm |

1190 |

1190 |

1190 |

1330 |

1250 |

|

Discharging height- mm. |

750 |

750 |

750 |

700 |

740 |

|

Electric Power hp/kw |

0.5 / 0.37 |

0.5 / 0.37 |

0.5 / 0.37 |

1 / 0.75 |

2 / 1.5 |