Listing ID #4024818

Company Information

Ask for more detail from the seller

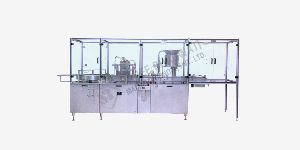

Contact SupplierThe Vial Filling and Plugging Machine was made to help in the filling of injectable glass vials with liquid. The machine majorly consists of a conveyor belt, turntable, pre-gassing, filling and post-gassing aspects. This Plugging and Capping Machine is made of stainless steel material of 316L quality which passes the GMP standards and assures the best return on investment in the longer run as well. Synthetic rubber tubes have been made and compact panel allows easy reachability.

Since the distance between filling and stoppering is pretty less, the risk in getting any contaminations reduces considerably. The Automatic Filling Plugging Machine clearly needs a sterile environment to work in. It also offers a laminar flow protection. Redesigning of the un-scramble has been done to remove the dead ends and clean the machine properly.