Listing ID #3943122

Company Information

Ask for more detail from the seller

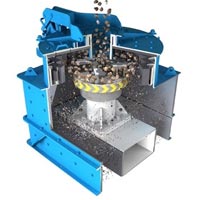

Contact Supplier| We are well known manufacturers and suppliers of Vertical Shaft Impactor, used in crushing material for various industries. These Vertical Shaft Impactor are known for their high performance and efficiency. They are easy to operate and require less technical expertise to function. As these Vertical Shaft Impactor are manufactured using quality raw material procured from trusted vendors. We offer these products at really affordable prices. | |

|

Benefits of using VSI |

|

|

|

|

Salient features of using VSI Crusher |

|

|

|

|

Specification |

VSI-450 |

VSI-650 |

VSI-900 |

|

Max. Feed Size (mm) |

40 |

60 |

100 |

|

Max. Input capacity (TPH) |

35-45 |

80-90 |

200-220 |

|

Impeller (RPM) |

1700 |

1250 |

1250 |

|

Required Power (HP) |

75 |

125 |

300 |

|

Impellers per table |

3-4-5 |

3-4-5 |

3-4-5 |

|

Rotor Type |

Open-close |

Open-close |

Open-close |