Listing ID #6654388

Company Information

Ask for more detail from the seller

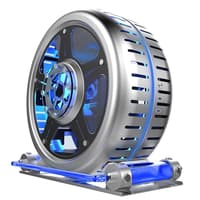

Contact SupplierFor catering the variegated demands of our respected clients, we are highly engrossed in providing a wide range of Vertical Sand Cooler.

Designed for dedusting and cooling molding sand (bulk materials with a fraction of 0.08 mm to 0.8 mm with a density of 1.2-1.8 tons per cubic meter) to the operating temperature. Works on the principle of "fluidized bed". Water heat exchangers are installed in the "boiling" zone of the sand, they are used in the summer. The high-pressure fan creates a fluidized bed of sand. The air passing through the hot sand takes heat and dust fraction, then it enters the cyclone-type dust collector through the aspiration branch. After the cyclone, another fan is installed to equalize the air pressure in the cooler.

The cooler is supplied with an aspiration system. A temperature sensor is installed at the outlet cooler, which allows you to control the temperature of the sand. The temperature of the sand at the outlet of the cooler depends on the cooling time and the temperature of the air supplied to the cooler. The sand cooling time can be adjusted according to the time of operation of the air damper for unloading.

Part of the equipment:

The technological unit is designed for cooling molding sand. The sand cooler uses the "fluidized bed" principle, i.e. Atmospheric air passes through the sand layer at high speed, causing it to boil. The air that cools the sand carries the dust fraction into the cyclone, and, having passed it, purified, is released into the atmosphere. A water heat exchanger is installed in the sand boiling zone, which speeds up the cooling process. The time spent by the sand in the cooler can be adjusted by the operator from the control panel by closing the pneumatic valve when unloading into the elevator.

In our LFC equipment, we use an air sand cooler with a built-in water heat exchanger and, depending on the climatic zone of use of the equipment and its performance, we supplement the sand hopper with another water heat exchanger. This scheme allows you to guaranteed cool the foundry sand to its operating temperature.

The use of a sand cooler designed by Castofoam India Pvt. Ltd is possible not only in the LFC process, but also in any technological process where quartz sand with similar temperature parameters is used (in the production of building mixtures, glass production, etc.)

We, Castofoam India Private Limited are one of India’s prominent manufacturers, exporters, and suppliers of casting machines and equipment. We deal in process casting plants, lost foam casting plants, lost foam casting machines, 3D lost foam compaction tables, automatic lost foam compaction tables lost foam mold boxes, lost foam sand coolers, LFC box tilting devices, and LFC automatic molding lines. We are committed to providing our clients with uncompromising quality in our products. Located in one of the finest places in Ahmedabad (Gujarat), we supply our products to different parts of the world.

Our Team:

We are blessed with a team of professionals who are aware of the goals of the company and work for achieving the same. Each and every employee in the company has in-depth knowledge and a better understanding of this field. We have manufacturing personnel, talented engineers, quality control specialists, supervisors, managers, logistic & transportation personnel, and other allied workers in our company.

Quality Assurance:

All of our products are designed and developed by skilled professionals using quality-approved materials and sophisticated technology. All strict quality-control methods are used to examine the sourced raw materials and manufactured machines & equipment. Our quality control specialists remain watchful during the whole production process so that the manufactured products will be error-free. They make sure that all of our products must match the required standards.

Our Facilities:

We are backed by a sound infrastructure that includes all the facilities needed for good production. Our infrastructure includes a manufacturing unit, R & D unit, quality control unit, logistic department, etc. All of these facilities are installed with the necessary machines, tools, and advanced technology to accomplish all the tasks properly.

Client Satisfaction:

We strive to impress our clients by offering them good products at a reasonable price range. We adopt a unique approach to conducting our business deals and look forward to creating strong bonds with our clients in order to ensure their continued contentment.