Listing ID #3813731

Company Information

Ask for more detail from the seller

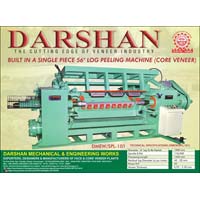

Contact SupplierSpindle veneer peeling machines

Veneer peeling machine 56” (1400mm), 1350mm, 2600mm and Face veneer peeling lathe 108” (2750mm) and other models according to our customer’s specific requirements.

Spindle less log peeling machine, 1350mm, 1400mm, 2600mm & (2750mm) and other models according to our customer’s specific requirements.

We are also manufacturing hydraulic veneer peeling machines in CNC/ PLC systems according to our customer’s requirement.

We are also leading manufacturers, exporters and suppliers of veneer cutting machines. These machines are widely used in the all kind of plywood & veneer making industries for cutting core veneers & face veneers. These machines are fully automatic because in these machines has a conveyor system for feeding & out coming processes veneers. Rapidly production about these machines as compare to conventional method, in conventional method for veneer cutting purpose some manual hand chopping & peddle chopping machines are used result very low production & costly. These machines are also known as plywood cutting machines.

MACHINE’S FEATURES:

Veneer Peeling Lathe Machines are available in different models and also manufacturing different sizes of working diameter, working length and veneer thickness according to our customer’s requirement.