Listing ID #3929293

Company Information

Ask for more detail from the seller

Contact Supplier

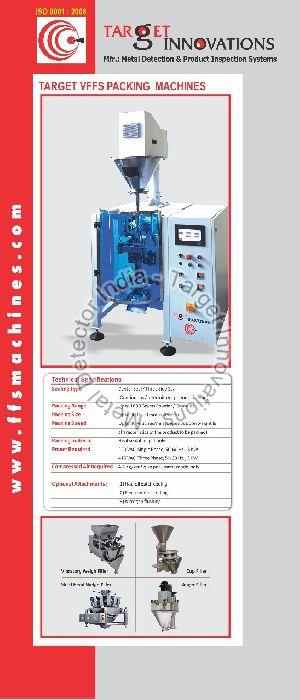

The machine is operated via man machine interface two line screen with integral PLC. All machine parameters are adjusted and saved within this interface resulting in a very flexible and quick change over machine

Features:

NOTE

|

* Depends on Material, Filling Range.

|

|

** We can supply as per customer requirements.

|

|

*** With help of change parts.

|