Company Information

Ask for more detail from the seller

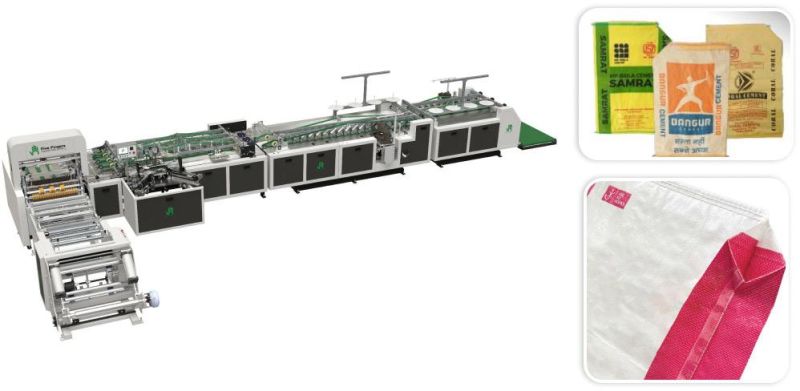

Contact SupplierIndia's First Gusseted Valve Bag-Making Machine

Introducing our VALVO Series, India's First Gusseted Valve Bag Making Machine by Five Fingers Exports India Pvt. Ltd. This fully automatic PP woven valve bag-making machine sets new standards in performance and efficiency for high-speed production.

Engineered to excel, it meets the rigorous demands of manufacturing valve bags essential for cement, food grains, salt, sugar, chemicals, fertilizers, minerals, and other pulverous and granular materials. With its superior precision and efficiency, the FFN VALVO Series ensures unmatched productivity and reliability.

Key Features:

High Efficiency: Produces up to 40 valve bags per minute, ensuring high-speed and efficient production.

Accurate Valve Dimensions: Ensures precise valve dimensional accuracy for better packaging efficiency.

Low Energy Consumption: Designed to be energy-efficient, reducing operational costs.

Low Maintenance Cost: Engineered for durability and ease of maintenance, lowering overall maintenance costs.

Versatile Processing: Capable of processing both laminated and non-laminated fabric.

Technical Specifications:

Components and Functions:

Unwinding Unit:

Edge Position Control Unit (EPC): Automatically adjusts to align the web with precision.

Easy Mounting: Allows easy mounting of the tubular woven fabric without external lifting devices.

Hot Cutting Unit:

Mouth Opening Device: Opens the leading edge of the cut length, suitable for un-laminated fabric.

Cut Preset Length: The Servo motor ensures precise cutting of fabric at preset lengths.

Transfer System:

Valve Forming: Servo-controlled transfer system delivers bottom folded and stitched bags to the valve forming unit, followed by top-end double folding, stitching, and delivery to the stacking unit.

Accumulator Unit:

Print Mark Sensor: Ensures precise cutting of fabric.

Uniform Tension: Maintains consistent fabric tension throughout the machine, aiding in precise cutting and accurate print mark detection.