Listing ID #3962022

Company Information

Ask for more detail from the seller

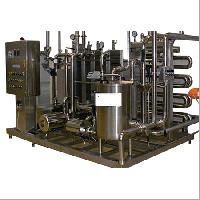

Contact SupplierOur Adiabatic Vacuum Continuous Crystallizers operate on the principle of ‘adiabatic boiling’ wherein the feed liquor is exposed to high vacuum resulting in evaporation and cooling of the liquor.

The concentrated liquor is fed to the continuous crystallizer in an acidic or alkaline condition. At the point of super saturation, the salt present in the liquor starts crystallizing and the vapours generated are compressed with the help of steam jet boosters. The continuous crystallizer operating with multi-nozzle boosters offer the most optimized operational costs.

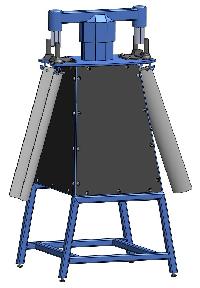

Batch Vacuum Crystallizers

Our Adiabatic Batch Vacuum Crystallizers are used for cases requiring very low operating temperatures achieved only by very high vacuum, and for those applications involving relatively small amounts of material, or when the material being processed must be handled on less than a continuous basis, it is often both convenient and economical.

Where the material is cooled through a very wide range and/or to a final temperature which requires very high vacuum, a large ejector or booster is utilized to compress the vapor to a pressure high enough for condensation with available cooling water. In such cases, the batch vacuum crystallizer steam economy is achieved by multiple stage continuous equipment of five or more stages.

Key Advantages