Listing ID #953005

Company Information

Ask for more detail from the seller

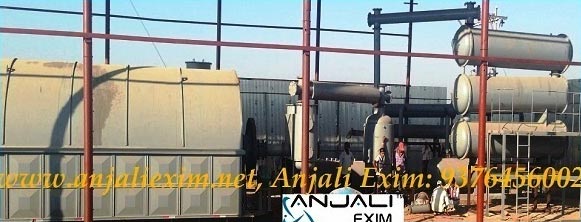

Contact SupplierWe offer highly efficient Tyre Recycling Plant that is used for recycling the waste tires. The output after the recycling process includes carbon black, furnace oil, steel and gas. Our Tyre Recycling Plant is known for its easy installation and low maintenance. Tyre Recycling Plant makes use of plastic rubber (tyres) life garbage and requires about 8 to 10 tons of waste tires as a capacity for single batch.

Project Planning & Implementation (For the 10 ton/day capacity)

Other Arrangements to be made by Client

Storage tank of oil (Available locally), Civil Work, Local Worker & labour, Hydro crane, Plumber, Electrician, Gus cutter, Welder.

Terms & Condition

Estimated Operational Cost and Return on Investment

Total output

Advantages :

Project ( Dimension : 6.6 *2.6m)

| Equipment | Specification |

|---|---|

| Equipment Model | AZ-150 |

| Material | Plastic rubber (tyres) life garbage |

| Structure | Horizontal tyre revolves |

| Capacity For One Batch | About 8-10 tons wastage tyres |

| Oil Yield | 45%-50% |

| Carbon Black | 30%-35% |

| Steel Wire | 10%-15% |

| Gas | 5%-8% |

| Work Pressure | Normal |

| Main Engine Rotation Speed | 0.4 RPM |

| Fuels Choice | Coal, Wood, Gas, Oil |

| Power | About 35 HP |

| Cooling Method | Water |

| Cooling Water Consumption(T/H) | Cyclic |

| Type Of Drive | External Annual Gear Drive |

| Heating Method | Direct |

| Type Of Installation | With Foundation |

| Operating Mode | Intermittent Operation |

| Reactor Dimension (MM) (Long*Diameter) | 6600*2600 |

| Reactor Weight | About 28000 Kg. |

| Total Weight | About 38 MT |

| Name | Weight | Size (MM) | Quantity |

|---|---|---|---|

| Reactor | 28000 kg | D2600*6600 | 1 |

| Catalyst Chamber | H2100*L1800 | 1 | |

| Oil Water Separator | D1200*H2380 | 1 | |

| Oil Tank | D1000*L3200 | 3 | |

| Horizontal Condenser | D900*L3700 | 3 | |

| Horizontal Condenser | 300kg | D426*L3700 | 2 |

| Anti-back fire device | 50 kg | D650*H1600 | 1 |

| Buffer Tank | 50 Kg | D550*H1350 | 1 |

| Negative Pressure Device | 890 Kg | H2050*W2000 | 1 |

| Water Jet Condensing Pipe | D500*L4000 | 1 | |

| Dust Removing device | 2000kg | H800*L3070 900*1050 |

2 |

| Draught Fan | L950*W800 | 1 | |

| Chimney | 200kg | 20FT | 1 |

| Auto Feeder | 400Kg | L4700*W1200*H2150 | 1 |

Note : D = Diameter L = Length H = Height W = Wide

| Particular | Investment |

|---|---|

| Building and land (1500sq.meters with 600sq.meters shade) | Depend on the area |

| CHINESE PLANT | |

| Price of the Plant (Ex – Factory China) 7th Generation With Auto feeder ( Dimension:2.6*6.6MT) | 60,000 USD |

| Custom Duty 26%, Freight, Container Clearing Charges, Transportation Extra. | 55,000 USD |

| This does not include the rate of interest on capital investment. | |

| Product | Output (%) | Output (Ton) | Price Per ton. | Total Income |

|---|---|---|---|---|

| Carbon Black | 30.00% | 720 | 1000 | 7,20,000 |

| Furnace oil | 45.00% | 1080 | 40000 | 4,32,00,000 |

| Steel | 12.00% | 288 | 13000 | 37,44,000 |

| Gas | 8.00% | 192 | --- | 0 |

| Total (A) | 4,76,64,000 | |||

| Particular | Quantity | Price | Total Cost |

|---|---|---|---|

| Waste Tyres | 2400 | 14000 | 3,36,00,000 |

| Salary & Wages | 9*12 Month | 10000 | 10,80,000 |

| Fuel (For Initial Use) | 300 | 6000 | 18,00,000 |

| Electricity + Water | --- | -- | 8,20,000 |

| Misc. Expense (Bag Packing, Repairing, Renovation) |

--- | -- | 9,50,000 |

| Total (B) | 3,82,50,000 | ||

| Profit (Earnings – Expenses) (A-B) | 94,14,000 |