Company Information

Ask for more detail from the seller

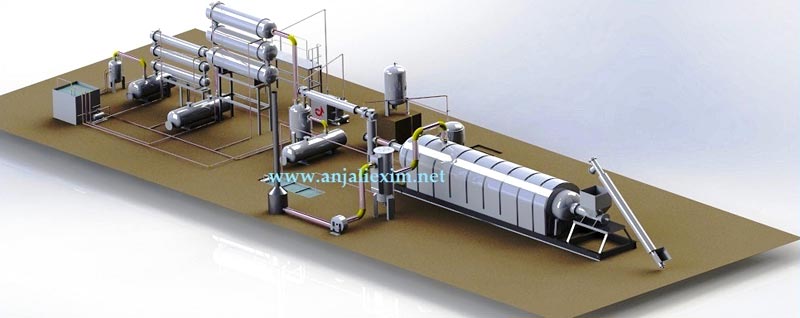

Contact SupplierTyre Pyrolysis Plant that we offer is used for recycling the waste tires. Our Tyre Pyrolysis Plant is environmental friendly as it does not make use of any chemical ingredients during the process. Further, there is zero soil, water and air pollution is created after the process. Our Tyre Pyrolysis Plant is the most cost-effective and efficient way to recycle the waste tires.

Features of the Plant

Technical Detail

Advantages :

Security :

Environmental Friendly :

Full open door design :

| Equipment | Specification |

|---|---|

| Equipment Model | AZ-150 |

| Material | Plastic rubber (tyres) life garbage |

| Capacity For One Batch | About 8-10 tons wastage tyres |

| Work Pressure | Normal |

| Main Engine Rotation Speed | 0.4 RPM |

| Fuels Choice | Coal, Wood, Gas, Oil |

| Power | 35 HP |

| Cooling Method | Water |

| Cooling Water Consumption(T/H) | Cyclic |

| Type Of Installation | With Foundation |

| Reactor Dimension (MM) | 6600*2600 |

| Reactor Weight | About 28000 Kg. |

| Total Weight | About 38 MT |

| Land Require | 12,000 to 15,000 Sq Ft |

| Construction Shed | 40 * 80 Ft = 3200 Sq Ft |

| Water Require | 1000 Liter Per Process |

| Manpower | 1 Manager, 2 Technician, 7 Worker |