Listing ID #3960081

Company Information

Ask for more detail from the seller

Contact SupplierDelta Twin Screw pumps work on unique principle that makes it the only choice for certain applications. No other design of Positive Displacement Rotary pumps offer so much versatility in the operating parameters with guaranteed total reliability and maintenance-free service.

Delta Group have earned a reputation of providing the most reliable Positive Displacement Pumps for practically any given application since 1968 due to the widest choice of designs available and excellent knowledge of application engineering. Continuous Research and Development together with modernization with CNC machines and testing facilities has enabled us to accept challenging jobs.

Several of Delta pumps in operation since decades to the total satisfaction of the users in core industries throughout the country and abroad are a silent testimony.

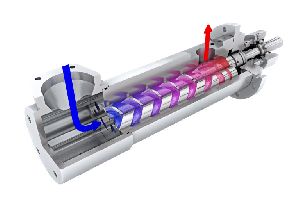

Working Principle

A pair of specially profiled screw, machined integral from solid stock and well supported on antifriction bearings run in precision bored interchangeable casing liners. Each screw set has one right hand and one left hand screw engaging with a similar but opposite hand screw pair.

A pair of hardened and profile ground timing gears synchronize the screws to maintain a small but positive clearance between the flanks thus ensuring no metal to metal contact. The pumps can therefore run dry for sometime without any damage. This unique feature enables to run the pump even dry and handle fluids that do not have enough lubricating value and also very low or high viscous products.

Consequently, since there is no metal to metal contact; wear and tear is reduced to the minimum, ensuring extremely long service life. With two pairs of screws running in the same casing, the internal velocities are very small - consequently the NPSHR is practically the lowest even when the pumps run at motor speeds and while handling viscous products. Opposed screw pitches totally eliminate axial thrusts. Relatively small diameters of screws enables the pump to operate at high speeds directly coupled to prime movers - without the need for speed reducers even while handling high sealing’s always under suction pressure, thus making use of simple, inexpensive seals.

The axial flow without turbulence, rotation, churning, chewing guarantees gentle handling of products. Noise and vibration or ---- levels are about the lowest. Positive clearance between running parts makes it easier to construct the pump in different materials safely, especially in stainless steel, without the fear of seizing. Thus a variety of fluids can easily be handled by selecting the right materials of construction.

Typical Parameters

Temperature: -30 to +350°C

Viscosity: 1 cSt to 50,000 cSt or more

Capacity: 20 to 500 m3/hr

Pressure: Normal 16 bar/ 24bar, with special designs upto 50 bar

Specialties: Partial heating/ complete heating/ cooling arrangements

Sealing: Stuffing box/ mechanical seal with or without quenching/ heating/ cooling

Mounting: Horizontal foot mount/ vertical pedestal

Accessories: Relief valves, base frame, coupling, coupling guard, companion flanges, pressure gauges, electric motor/ diesel engines, variable speed drives and as per customer requirements.

Salient Features

Positive clearance between rotors Insensitive to varying viscosities

No metal to metal contact between rotors Long maintenance free service

Dry running capability Lowest NPSHR

Negligible wear over years Shaft sealing at suction pressures

Axial smooth steady flow Axial thrusts completely eliminated

High speed running Interchangeable liner

Pulsation free output Adaptability of various MOC

Negligible vibrations

Typical Applications

Loading / unloading of fuel oil and other products from: Railway wagon rakes, Truck tankers, Barges, Ships and Tankers.

Bulk cargo handling.

Lubrication, circulation and cooling.

Process pumping of high viscous products, bitumen, molasses, soap and similar products.

Long distance pipeline pumping of viscous products.

Typical Liquid List

Additives Paraffin

Base oils Petroleum products

Bitumen Polyester

Fuel oils - all grades Residues

Lubricating oils - all grades Soap

Lyes Vegetable oils

Molasses

Major Industries

Petroleum refineries, Terminals, Depots, Oil blending stations, Thermal power plants, Steel plants, Fertilizer industries, Petrochemical plants, Carbon black, Sugar, Paper and Pulp, Marine.