Listing ID #3860539

Company Information

Ask for more detail from the seller

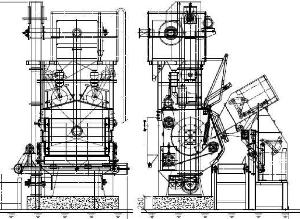

Contact SupplierMechanical loaders are used for the machine on special request. The Shot blast machines can receive the parts to be cleaned directly or using separate transport bins of the standard sizes.

SSEC blast wheels are renowned for high capacity and maximum energy efficiency. These blast wheels come in various power ratings, giving a high degree of flexibility. With modifications it is possible to reverse the blast wheel rotation thus allowing a greater range of applications. The amount of abrasive can also be adjusted. The abrasive is mechanically pre-accelerated and delivered to the blast wheel in a continuous stream, this ensures optimal utilisation of the power from the drive motors. High wear resistant material ensures maximum service life of the blast wheel. Unique features allow for rapid and simple replacement of wear parts.