Listing ID #4171502

Company Information

Ask for more detail from the seller

Contact SupplierLubrication science has greatly improved energy efficiency, health and personal care. Lubricants are mainly categorized by their ability to prevent wear and reduce friction in a variety of test conditions. Manufacturers of lubricants use increasingly complex additives to lubricants to optimize performance. However, in order to effectively tailor lubricants to specific applications and produce “designer” lubricants, one must understand the fundamentals of how molecules in a lubricant interact with surfaces and more importantly, change when subjected to mechanical shear. It is important to understand these parameters and how they influence friction.

In many cases, the change in molecules when subjected to tribological tests are reversible and therefore undetected by traditional test methods. With the use of an innovative tool like the Ducom TriboChemist, researchers can now access in-situ data from a test to characterize chemical and tribological behavior of a lubricant.

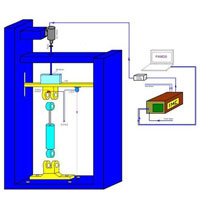

The Ducom TriboChemist combines an Infrared Spectrometer with Attenuated Total Reflection (ATR) crystal and a specially developed Linear Reciprocating Tribometer (LRT). This integrated system includes a friction sensing module for acquiring the tribological component of tests conducted on the TriboChemist.

The system can house a cylinder, pin or a ball as the moving (upper) specimen which is pressed against an ATR crystal surface to produce a point, line or an area contact. Users can program the TriboChemist to customize tests by configuring stroke length (displacement), sliding speed, test load (contact pressure), and duration of test. Temperature and humidity control are also possible.