Company Information

Ask for more detail from the seller

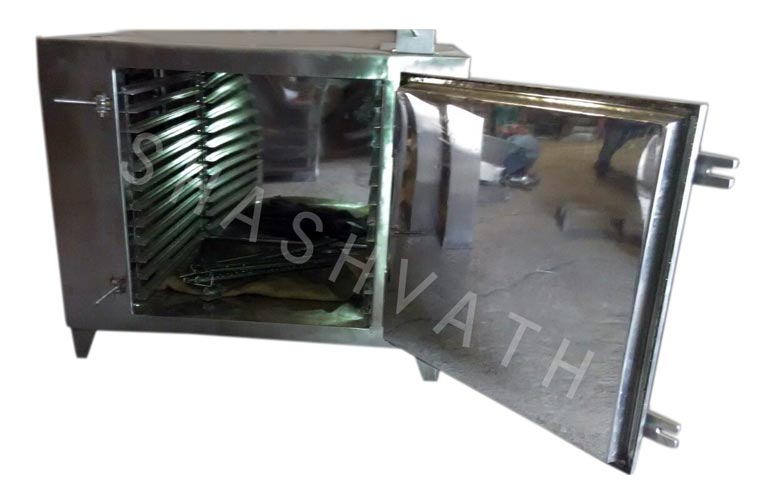

Contact SupplierAt Shashvath fabricators and engineers, we manufacture and supply the Tray Dryers from Thane, Maharashtra. These try dryers are specifically used for drying small granules and particle sized food materials in pharmaceuticals and food industries. Through the dryer, heat is applied directly to make the solid and liquid materials dry. The product is very efficient in its use and promises durability.

Salient Features of Tray Dryer :

High quality, Efficient performance, Cost effective

Heater system for either pressurized hot water or diameter thermal fluid

Solvent recovery system with condenser and receiver, vacuum pump and ancillaries, characteristics and dimensions depending on the drying processes

All contact parts made of SS 316 as PGMP standard

Available in wide range models from 6 to 192 raise capacity

Design for uniform circulation of hot air in the drying chamber

Heating cold and fan motor having electrical inter locking for safety of heating elements

Fresh air inlet and outlet air flow can be adjusted with damper control valve

Electric/Steam/Thermic Fluid heating system.

Optional Features :

Heating system Electrical / Steam / Gas Heating.

Separate Inlet AHU with HEPA Filtration.

Perforated tray

Standard Painted Model.

Safety Features :

Automatic Temperature & controls, Process cycle controls.

Overload relay Protection and Emergency stop button

Construction | Our dryers will be of robust construction built on formed angles of 10 gauge sheet and suitable reinforced with angles and sections. The dryers internal and external walls are manufactured from 16 gauge thick mild steel sheets. The dryer will be insulated with minimum 75 mm thick glasswool insulation. The dryer will have a fresh air inlet through filter and an adjustable air outlet with a door at the front . The door will be explosion proof and will be locked with the help of spring loaded ball latches with suitable pressure. Door lips will have asbestos / rubber gasket to prevent leakages. |

|---|---|

Finishing | The dryer will be treated with 2 coates of Zinc cromate primer followed by internally with high temperature heat resisting aluminium paint and externally with synthetic enamel paint with black borders. |

We almost ensure to keep the high standard of our dryers by making them of robust construction and by using the best quality of raw materials with eye pleasing workmanship with uniform temperature. | |

Electrical Heating | Air inside the tray dryer will be heated by “U” tube air heaters each of 1000 watts. The heaters are fitted on the sides of the dryer to facilitate uniform heating. Maximum temperature attained inside the dryer will be 100/200/300’C and will be indicated by a dial thermometer fitted on the dryer . Temperature inside the dryer will be controlled by a thermostat over full range of heating load. |

Steam Heating | Air inside the dryer will be heated by two steam calorifier made out of mild steel pipes and tubes and suitably grooved by high conductive continuous galvanised fins. There will be two steam coils fitted diagonally opposite each to facilitate uniform and faster heating. Maximum temperature attained inside the dryer will be 100’C and will be indicated by a dial thermometer fitted on the dryer. |

THERE ARE 2 STEAM COILS IN ALL MODELS HOWEVER THEIR SIZES AND HEAT TRANSFER AREAS ARE DIFFERENT IN ALL MODELS. | |

Air Circulation | Air inside the dryer will be circulated by one/two heavy duty axial flow blowers fitted on shafts of ¾” / 1 ¼” dia and driven by ½ TEFC motors of suitable HP. With ISI mark through belt. The special design of the motor ensures uniform air circulation o that there is uniform air current over the entire charge loaded inside the Trolley inside the dryer. The working of the motor will be indicated by lamps in the control panel. |

Trolley/Rack System | Models with 12 & 24 trays have a fixed rack system made out of mild steel angles. Model with 48 trays will have one trolley, Models with 96 trays will have 2 trolleys, models with 192 trays will have 4 trolleys and so on. Each trolley’s dimensions will be 840mm x 920mm x 1780mm . It will be made from MS angles and bars. Each trolley will have two fixed and two swivels wheels for movements. |

Trays | Trays will be manufactured from 16 or 18 gauge aluminium sheets. Its dimensions are 32” x 16” x 1 ¼” . Trays are also available in SS 304 / 316 , PP & FRP. |

Control Panel | Control panel will be fitted on the front of the dryer. It comprises of starter with overload relay, contactor, push buttons, thermostat, indicating lamps, connectors, etc. All components are wired up for connection with an earthing bolt. |

Models | TD-12 | TD-24 | TD-48 | TD-96 | TD-192 |

|---|---|---|---|---|---|

Loading capacity | 12 Trays | 24 Trays | 48 Trays | 96 Trays | 192 Trays |

External Dimension In (mm) | 1370X530X940 | 1370X940X940 | 1980X1020X1880 | 3320X1900X1880 | 3320X1900X1880 |

Internal Dimension In (mm) | 840X430X840 | 840X860X 840 | 1020X930X1830 | 1960X930X1830 | 1960X930X1830 |

No. Of Doors | One | One | One | Two | TWO |

No. Of Blowers | One | Two | One | Two | FOUR |

No. Of Motors/HP 3 Phase 415 Volts | 1/0.5 HP 3 Phase 415 Volts | 1/0.5 HP 3 Phase 415 Volts | 1/1 HP 3 Phase 415 Volts | 2/1 HP 3 Phase 415 Volts | 4/1 HP 3 PHASE 415 VOLTS |

Electrical Heating Load For 100’C/200’C/300’C | 3KW/6/KW/9KW | 6KW/9KW/12KW | 9KW/15KW/18KW | 15KW/21KW/27KW | 36KW/42KW/48KW |

Steam Heater No Of Coils | 1 | 1 | 2 | 2 | 2 |

Steam Pressure | 3.3 KG/CM2 | 3.3 KG/CM2 | 3.3 KG/CM2 | 3.3 KG/CM2 | 3.3 KG/CM2 |

Steam Consumption | 25 LBS/HR | 45 LBS/HR | 60 LBS/HR | 80 LBS/HR | 120 LBS/HR |

Insulation In (mm) 100’C/200’C/300’C | 50/75/75 | 50/75/75 | 50/75/75 | 50/75/75 | 50/75/75 |

No. Of Trolleys | Rack System | Rack System | One | Two | FOUR |

Tray Size | 812X406X31 | 812X406X31 | 812X406X31 | 812X406X31 | 812X406X31 |

Trolley Dimension | Fixed Racks | Fixed Racks | 840X960X1780 | 840X960X1780 | 840X960X1780 |