Listing ID #3954339

Company Information

Ask for more detail from the seller

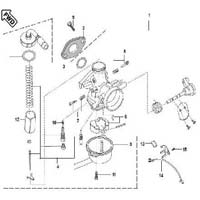

Contact Supplier( To prevent after burn in exhaust silencer during deceleration )

Applications : 4 - stroke : 100 cc - 150 cc, Motor cycles, scooters, 3 - wheelers, Mopeds

Options :