Listing ID #3934660

Company Information

Ask for more detail from the seller

Contact Supplier

As blast furnaces and converters have become larger and more efficient, the use of torpedo cars has increased as it prevents heat loss from hot metal and the cost of construction as well as maintenance is comparatively low

The torpedo car was originally used for transportation and storage of hot metal. But now hot metal pre-treatment (i.e. desiliconisation, desulphurization and dephosphorisation) has been separated from decarburization processing (done in a converter) and it is done in the torpedo car.

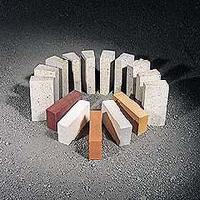

Based on the need for corrosion resistance against FeO, Na2O and CaF2, Al2O3-SiC-C bricks have been developed comprising of alumina as the main aggregate, graphite which provides resistance to spalling and slag penetration and SiC which protects graphite from oxidizing..

In different areas of Blast Furnace Ladle Car / Torpedo Ladle

| Properties | Metal contact | Slag line | Ceiling | Impact Zone |

| Chemical composition, % Al2O SiO2 SiC Residual Carbon |

86 5 7 16 |

73 2 7 16 |

75 1 5 16 |

66 0.5 9 20 |

| Apparent porosity, % | 7 | 8 | 7 | 7 |

| Bulk density, g/cm3 | 2.89 | 2.89 | 3.02 | 2.85 |

| Cold crushing strength, MPa | 52 | 30 | 47 | 47 |

| Apparent porosity, % | 16-18 | 12-14 | 15-19 | 20-23 |

| Modulus of rupture at room tem. MPa | 12 | 10 | 12 | 11 |