Listing ID #1627191

Company Information

Ask for more detail from the seller

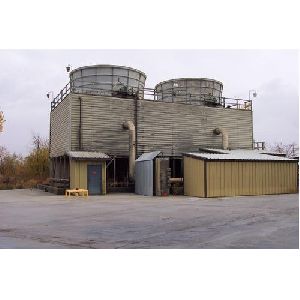

Contact SupplierWe are leading manufacturer of timber type cooling towers.It is mechanical strength, durability and high efficiency. Manpower with vast specialized experience in Timber manufacturing is back bone of the organization. We have with us persons who have been entirely responsible from concept to final product manufacturing. We have major time tested development that has been incorporated in standards. Our CCT timber are atmospheric and mechanical cooling towers. Atmospheric towers are only for smaller capacities and mechanical draft towers are for higher range. Induced draft cooling towers are efficiency and popular due to sucking of air from the tower and exhaust at the top or side. The timbers are made out of pine or chirr wood after properly seasoned and chemically treated with arsenic chromate to with stand its life against biting, fungus and termite etc.

Timber Cooling Tower Product RangeOur Timber Cooling Towers are designed for the highest effieiency at the lowest operating cost. Fans gear boxes, fill and drift eliminators are optimized to deliver maximum cooling with minum applied horsepower for lower operating cost.

1.2 Best PerformanceOur Timber Cooling Towers are providing more wetted surface area for uniform water distribution and higher heat trasfer rate.

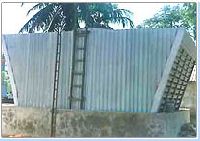

1.3 Architectural CompatabilityOur Timber Cooling Towers are designed to a low profile. So the appearance and general configuration blends harmoniously with surroundings. Performance and attractive appearnance are demanded.

1.4 Maintenance FreeOur Timber Cooling Towers are used maintenance free materials throught the tower. The materials are used in structural and functional components, all steel is hot-dipped galvanized after the fabrication.

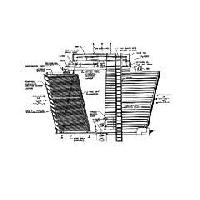

Timber Cooling Tower Technical Specifications2.1 Structure

Main structural components and other light sections machined with selected preservative timber. And it is designed for operational load and wind pressure of 250 kg/m2 of projected area in any horizontal direction. The structural timbers are made out of pine or chirr wood after properly seasoned and chemically treated to withstand its life against biting, fungus and termilte etc.,

2.2 FillsDifferent types of preservative treated wooden splash bars, PVC bars are used depending on applications. Different types of afill materials with different shapes area available according to suited design of applications. Fill bars are designed to offer maximum splash surface and wetted surface resulting in a high heat transfer rate.

2.3 Water Distribution in TimberBoiler waterproof plywood [marine grade] / treated timber are used for hot water chamber. For uniform distribution box through which the water is equally distributed in the hot water basin. Basins are provide with combination metering orifices / diffusers which distribute water uniformly.

2.4 Fan Cylinder in TimberFan cylinders designed in aero-dynamically the design allows close tolerance on fan blade tip clearance plus less interference of air passing through the tower. Fan cyclinder made by HDG Steel / Fiberglass reinforced polyester.

2.5 Nozzles in TimberThe Target Nozzles used in the hot water chambers are designed to deliver required water evenly. The nozzle eliminates the need for a deck to provide complete water distribution throughout the fill area. It is highly resistant to temperature and weathering damage the water is distributed under gravity.

2.6 Louvers in TimberThe standard cladding of profile corrugated asbestos cement sheet, the joints of which are lapped to shed water only inside the cooling tower. Louvers are supported and positioned by combination tower columns and louvers supports.

2.7 Drift Eliminators in TimberSpecially designed eliminators from single pass pattern to 4 pass pattern of various materials are provided according to applications to minimize bleed of losses. Two pass herringbone drift eliminators trap entrained moisture causing it to drain into the cooling tower basin.

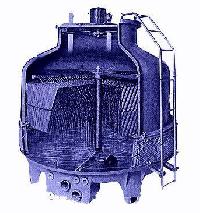

2.8 Mechanical Equipments in TimberThe mechanical equipments are used in our cooling towers are specially designed for long lasting life. Multiblade fans are cast aluminim for smooth quiet operation, Low Noise, high volumes of air High efficiency, and low power consumption adjustable pitch blades are used for maximum utilization of applied horsepower. Fans are driven by an electric motor coupled to a spiral bebel gear box through a dynamically balanced tubular drive shaft. We are using special enclosed motors with weather proof and in IP-55 construction to withstand moist air stream.

2.9 The External Casing in TimberThe External Casing is corrugated cement sheets fitted vertically and joints are lapped and sealed for water tightness. Corners are covered by absestos sheets. Also using FRP Sheets for External casing in Timber Cooling Towers.

2.10 Direct Drive Sytem in TimberThese are lower and medium capacity cooling towers and upto 10 feet dia fan are supplied with multiblade cast aluminum adjustable pitch fan with M.S. Fabricated HDG Hub and SS Hardware. Motor provided with the system is special low RPM totally enclosed vertical Flange type is supplied with the cooling tower. The motor is totally weather proof in IP-55 construction suitable for heated and humid atmosphere. In the above model fan is directly coupled wiht the slow RPM motors [vertical flange mounted with sealed top and enlarged threaded shaft]

2.11 Reduction Gear Box Drive System in TimberBigger capacity cooling towers are supplied with fan assembly driven through reduction gear reducer of spiral bevel type with the help of non-lubricated balanced drive shaft with flexible links. Fans are driven by an electric motor coupled to a gear box through a dynamically balanced tubular drive shaft. The compelete equipment will be supported on a single fabricated mild steel frame adequately weather proofed.

Counter Flow TowersPackaged Wooden Cross Flow Cooling Tower

Fan Less Natural Draft Cooling Towers

Timber Cooling towers are usefull for chemical plants, air conditioning plants, induction furnace, injection moulding machine, chilling plants, oxygen plants. diesel generating sets and heat exchangers. And also for steel industries, cement industries, chemical industries, water effuluent treatment industries. Our Timber are designed for the highest efficiency at the lowest operating cost. Fans, gear boxes, fill and drift eliminators are optimized to deliver maximum cooling with minimum applied horse power for operating cost. Our Timber provide more wetted surface area for uniform water distribution and higher heat transfer rate. The structural timbers are made out of pine wood (or) chirr wood after properly seasoned and chemically treated to with stand its life against biting, fungus and termite etc., Different types of preservative treated wooden splash bars, PVC bars are used depending on applications. Different types of fill materials with different shapes are available according to suited design of applications. Fills are designed to offer maximum splash surface and wetted surface resulting in a high heat transfer rate. The wooden fills are supported on FRP/SS grids which assure positive & permanent positioning and to assure uniform water distribution. We export and having many clients at USA UAE Dubai and Abudhabi.