Listing ID #3844536

Company Information

Ask for more detail from the seller

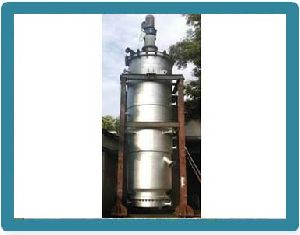

Contact SupplierThin – film Evaporators are vertical, Mechanically Operated Continuous Film Evaporator designed for difficult concentration, extremely heat sensitive materials wherein the unit operations like Distillation, Evaporation and Stripping can be conducted.

This technology gives the ability to remove volatile components from less volatile materials that are heat – sensitive, viscous, foaming, or contain solids. It offers short residence time, thin film formation by the centrifugal force of the rotating wiper system, the speed of which, can be adjusted to the viscosity of the product to be evaporated, which increase the evaporation efficiency. This is possible by the creation of the uniform film on the smooth heated surface of the glass body.

Of late, the demand for test and pilot plants for gentle distillation has considerably increased in Fine Chemicals, Pharmaceuticals, Foods & Beverages industry. The Constantly rising number of new products and rising world market price of raw materials are responsible for this demand.

Salient Features: