Listing ID #3693512

Company Information

Ask for more detail from the seller

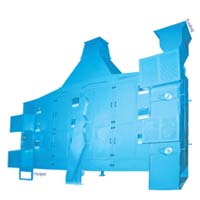

Contact SupplierIt is best in class for open width scouring & bleaching of fabric in batch form. It occupies less space and is capable processing cotton & blends in batches as big as 1600mm in dia. Also compared to conventional rope bleaching in kiers & pit pliers, it saves on manpower efforts as well. The machines are available in 1500mm to 3400mm dia.of fabric width.

Jumbo Jigger

Efficient consumption of chemicals

Besides comparatively low liquor ratio, AP 1000 has a pneumatic squeezing system which helps in maintaining temperature of

the fabric around 76 .0 for longer duration compared to an ordinary jumbo jigger.This reduces process time and consumption of chemicals.

Savings on labor

AP1000 needs one operator whereas 10 ordinary jiggers giving equivalent production need 5 operators. So if there are three shifts, saving would be equivalent 4 operators per shift amounting to 12 operators a day.

Occupies less space

Compared to conventional machines AP 1000 occupies less space. It fits in small space of 18. x 12′ which results in saving of vital shop floor space.

Quality Bleacher

In case of AP 1000 entire lot of fabric gets chemical treatment in one machine whereas in jiggers, different lengths of one lot are treated where parameters of liquor ratio, temperature of bath, time durations are likely to vary, which can lead to inconsistent bleaching results.

Saves water

In same amount of water consumption as jumbo jigger,AP 1000 delivers 4 times more efficient results.

Saves Power

A Jumbo Jigger needs 5HP drive

whereas AP 1000 is equipped with 7.5HP drive. Since the production of JT-10 is four fold as compared to Jumbo Jigger, savings of power would be 5 x 4 = 20 – 7.5 = 2HP per hour i.e.approx.175kw per day.

Extra attachments (optional accessories) which enhance performance of AP 1000

(1) Hood (2) Low liquor tank (type WS) (3) Intensifier with high pressure pumps and filtration (4) Auto temperature regulator