Listing ID #3955742

Company Information

Ask for more detail from the seller

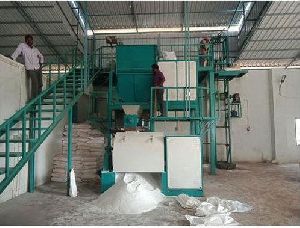

Contact SupplierPrecision Machinists supplies synthetic Detergent Plants for Powder, Cake and liquid soap.

1. Detergent Cake Plant

The Basic process comprises of all the raw materials being added into a mixer as per the sequence of the formulation and mixed till the reaction is complete. The mass is then extruded into bar or cake depending on the shape and size using plodder.

The equipment needed for a detergent cake are as follows:

| Sigma Mixer | Plodder | ||

| Lump Breaker | Cutting with Embossing Machines | ||

| Belt Conveyor |