Listing ID #4905254

Company Information

Ask for more detail from the seller

Contact SupplierSalient Features

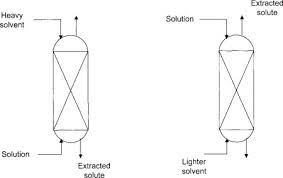

The Carbon dioxide gas from the cylinder is first liquefied & then pressurized above the critical pressure of CO2 (73.8 bar) to the required pressure necessary for extraction. This high pressure liquid CO2 is then heated above the critical temperature of CO2 (31 °C) to the required temperature. CO2 which is now in supercritical phase (SCCO2) enters the extractor where the raw material is fed in powder form & the extraction is achieved on the basis of solubility. The compounds dissolved in SCCO2 finally come to the separator at atmospheric pressure & get precipitated. CO2 leaving the separator is then measured by passing it through a CO gas flow meter.

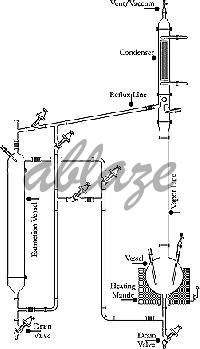

Process description for commercial scale plantThe raw material in powder form is fed to the extractor. The liquid carbondioxide from the CO2 tank is precooled by passing it through the precooler. This precooled liquid carbon dioxide is then pressurized by means of a positive displacement plunger pump to a pressure above the critical pressure of CO2 (i.e. 73.8 bar). High pressure liquid CO2 is then heated above the critical temperature of CO2 (i.e 31 °C) by passing it through preheater. CO2 which is now in the supercritical state enters the extractor in which the raw material is loaded. The SCCO2 dissolves substances on the basis of solubility, depending on operating conditions. The SCCO2 with soluble extracts enters the separators where the pressure & temperature are reduced sequentially so that solubility decreases & extract precipitates in the separators. Finally the clean CO2 without any traces is recycled back to the CO2 tank via condenser.