Listing ID #4614878

Company Information

Ask for more detail from the seller

Contact SupplierPurpose

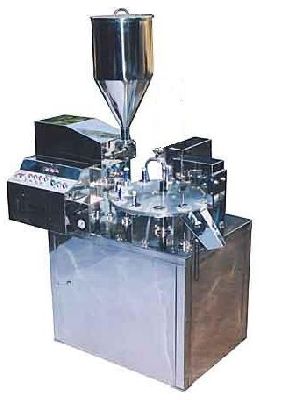

This machine is suitable for operating filling, sealing a quantity of viscosity of superglue,cynoacrylate in tubes

Filler-Digital pump base filler with special grade pipe.

Main Technical Parameter

Working principle

Automatic Tube Filling And Sealing Machine is designed for plastic tube and multiple tube filling and sealing in adhesives etc industries. It’s operating principle is to put the pipes which is in the feeder hopper into the first service position filling model individually, to invert with rotating disk, to test nomenclature plate in pipe when inverting to the second , to fill with nitrogen gas into pipe in the third, to fill with desired substance in the fourth, then to fix the heating, folding, jamming, number printing, cooling, slivers trimming etc service position, to export the finished products when inverting to the last service position so the twelfth. Every pipe should take such series process to filling, sealing to completion.

Capability and features

Accuracy filling, balanced action, low buzz.

1. Automatically finished overall process as tube supply, photoelectron register, inert gases filling (optional), material filling and sealing, batch number printing, finished products output.

2. Adjust position outlay and position numbers video picture, quickly and accurately adjustment ( suitable for varies specification and varies product producing )

3. Mechanical, photoelectron, electric, pheumatic intergrative controlling, reaches no tube no filling function; warning if tube error positioned or pressure too low, automatic stop machine if open the protective door.

Reliability

1. The part contact direct with ointment adopts 304L or 316L stainless steel. It use materials that is non-poisonous, no reaction with drug, non-corroding, no absorption from drug.

2. Inner workshop should smears anti rust coat that withstand weak acid and weak base besides adopts austenite stainless steel. The parts with chemical treatment should have no rusteaten and no exfoliation.

3. External surface should adopts austenite stainless steel wiredrawing board or sub-light treatment.

4. Semi-closed outline board visible window adopts bright, staticfree material as closed retaining band.

5. Table-board adopts nodular graphite foundry iron. It takes stress relieving, annealing and natural seasoning treatment to reduce distortion after usage.

Fully automatic 502 liquid glue tube filler and sealer owns the advantage of smooth surface, non-dead angle, non-toxic

Automatic 502 liquid glue tube filler and sealer produced by our company is in compliance with GMP requirements from the process of design, manufacture, assembly, testing, as well as parts of the main materials.

It owns the advantage of smooth surface, non-dead angle, non-toxic, tasteless, non-polluting, clean and maintain easily.

Compact conformation, easy operation. 502 liquid glue could be injected into the aluminum tubes through the filling system smoothly and accurately.

It finishes the process of filling, sealing and lot number (the date of production) printing on the aluminum tubes through the robot hands.

The max production capacity reaches to 3000 per hour; the filling volume error is within ± 1%.