Listing ID #2078160

Company Information

Ask for more detail from the seller

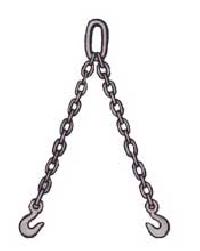

Contact SupplierWe are offering steel wire rope sling.

wire rope slings are made from quality wire ropes and end fittings, these slings are available against orders only with very short delivery period. Ropes are largely being converted into slings as slings find variety of applications in engineering industries, construction and material handling. In addition to standard slings, tailor made slings are made to cater specific applications. Slings are usually made out of high tensile ropes to make them light and incorporate high carrying capacity. Standards are available for the users to refer for fabrication, installation, usage and maintenance of slings.

slings are constructed to meet nearly every need. Of course, there are many special situations, which require the use of a specialty sling. These are also available when ordering a specialty sling be sure to consider:

maximum load

type of material to be handled

condition of material

lifting attachments

dimensions of load

height of lift

headroom and working space available

distribution of load weight

load center of gravity

number of sling legs required

ordering wire rope slings

when ordering slings specify the sling diameter and length are required ; the dimensions and fittings indicated will be supplied. When variations are necessary full dimensions must be specified. For example alloy oblong links are standard or most bridle slings, and these will be supplied unless otherwise specified. If oblong or pear-shaped carbon inks are desired, full link dimensions should be included.

rated capacities

rated capacities suggested for lifting slings are based on sound engineering practices and ample design factors. And are in accordance with occupation safety and health administration standards. Rated capacities are only applicable for new slings under normal conditions. As a standard practice to avoid confusion.

wire rope construction

wire ropes, which are regularly used in lifting slings, are either 6 x 19 class 0r 6 x 37 class. Generally. The choice between the two classes may also depend upon the application of the sling, and the characteristics that are most desirable in the sling. For example, if resistance to abrasion is of prime importance, the 6 x 19 class is chosen because wires of large diameter provide a high degree of wear resistance. On the other hand, if flexibility is desired, the 6 x 37 class is more satisfactory because of the large number of smaller wires in the rope other constructions may be available. But they are rarely used.

wire rope sling inspection

conditions such as the following should be sufficient reasons for consideration of sling replacement.randomly distributed broken wires in one rope lay.

for cable laid and braided slings of less than 8 parts, twenty (20) randomly distributed broken strand per sling.

for braided slings of 8 parts or more, forty (40) randomly distributed broken wires in one braid, or two (2) broken stands per sling.

severe localized abrasion or scraping.

kinking, crushing, bird caging or any other damage resulting in distortion of the wire rope structure.

evidence of heat damage or if a wire rope sling having a fiber core is exposed to temperatures un excess of 200°f

end attachments that are cracked, deformed, or worn.

hooks that have been opened more than 15% of the normal throat opening measured at the narrowest point or twisted more than 10° from the plane of the unbent hook.

corrosion of the rope or end attachments.

unlaying or opening up of a tucked splice.