Listing ID #4004585

Company Information

Ask for more detail from the seller

Contact Supplier

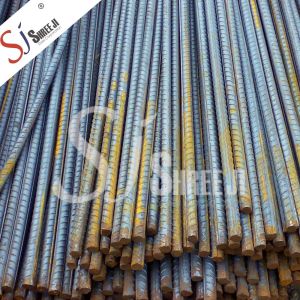

Meenakshi believes in producing the best quality TMT bars by keeping the consumers in mind. We are proud to be ISI certified manufacturers of Fe 500D grade of TMT bars in our Hosur plant.

There is a supreme connection between steel and concrete. Concrete has only high compressive power, and hence when it is combined with the TMT steel bars, together they become ductile and highly tensile. TMT bars can be used in a variety of projects like bridges, dams, flyovers, buildings, railways, etc.

What is Fe 500D?

Fe 500D is much more ductile than the Fe500. The letter “D” in Fe 500D implies ductility which means that the TMT steel bars have a higher percentage of elongation. They also have lower quantities of carbon, sulphur and phosphorous, which helps in preserving the steel and resisting earthquake shocks in future. These types of steel bars are produced under regulated manufacturing process and can be bent easily. This enables the fe500D to withstand the sudden load adsorption capacity, which is encountered during earthquakes, cyclones, Tsunamis etc providing higher safety. The main advantages of using Fe 500D TMT steel bars are as follows:

Meenakshi manufactures finest quality Fe 500D TMT bars using premium quality raw materials. To maintain high quality and exact weight as per ISI Standards, we have installed a well advanced TMT steel manufacturing plant. Each and every batch of Meenkashi TMT bars go through a rigorous process of Spectro lab testing. Before being approved under their standard grade we re-check its chemical properties, tensile strength in addition to other parameters. This helps maintain superior quality and exact weight standards for all the products.

At Meenakshi, Fe 500D TMT Bars are thermo-mechanically-treated by using advanced technology for high yield strength. Our broad range of TMTs and structural steel are widely used for general purpose in industrial construction, concrete structures like bridges and flyovers, and in infrastructure developments like construction of Apartments, Multistory Buildings, Dams, Railways, and Power Plants.

| Sizes Available | |||

| (Applicable to all grades as per IS: 1786: 2008) | |||

| Standard Dia | Nominal Weight | Range of Weight for Batch | |

| mm | Kg./mtr. | Kg./mtr. | Kg./mtr. |

| 6 | 0.222 | 0.206 | 0.238 |

| 8 | 0.395 | 0.367 | 0.423 |

| 10 | 0.617 | 0.574 | 0.660 |

| 12 | 0.888 | 0.843 | 0.932 |

| 16 | 1.579 | 1.500 | 1.658 |

| 20 | 2.467 | 2.393 | 2.541 |

| 25 | 3.855 | 3.739 | 3.971 |

| 28 | 4.836 | 4.691 | 4.981 |

| 32 | 6.316 | 6.127 | 6.506 |