Listing ID #3888110

Company Information

Ask for more detail from the seller

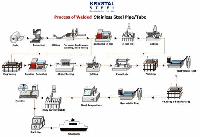

Contact SupplierThe process commences with the formation of welded mother tube on the tube mill from imported and tested prime quality stainless steel strips. The latest TIG multi electrode welding technique is employed for superior weld quality and 100% Fusion, with argon purging, No filler metal added.

These mother tubes are solution annealed at 1060 D. 1100 D. C in continuous annealing furnace followed by immediate quenching to prevent chromium carbide precipitation.

Annealling of mother tuber ensures:

A) Removal of stress induced during tube forming and cold drawing:

B) Sufficient ductility and softness for cold drawing:

C) Transformation of the weld zone to austentic nature,

D) Re crystallization of metallic grains to original form and thereby improving corrosion resistance.

During annealing, scales are formed on the surface of the tubes. In order to remove these, the tubes are pickled by immersing into hot pickling solution made of nitric acid, sulphuric acid and hydrofluric acid.

The tubes are then coated with proper lubricant and then cold drawn over a drew bench:

1) To vary the metallurgical structure and restore the properties to the parent material:

2) To achieve a tube having closer dimensional tolerances:

3) To achieve a tube having closer dimensional tolerances:

4) To produce tubing of smaller size and wall thickness.

5) To reorient the grain structure of weld portion with that of the parent material and

6) To remove/minimize the internal bead.

Drawing is followed by subsequent annealing and pickling to restore the properties of the entire tube to that of the parent material. The tubes are then passiated to impart extra corrosion resistance. Thereafter every tube is electrically marked with material grade, size and manufacturing standard.