Company Information

Ask for more detail from the seller

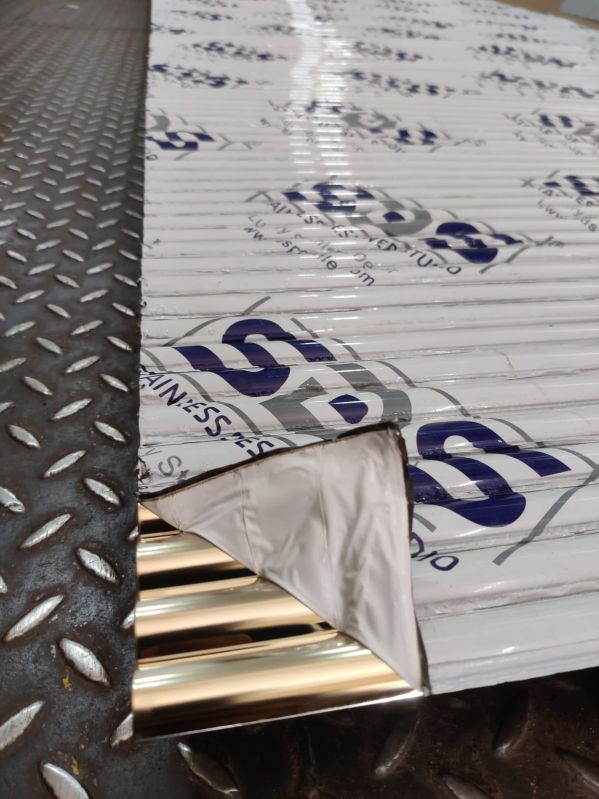

Contact SupplierWhat are Stainless Steel Fluted and Hat Type Profiles?

Stainless Steel Fluted and Hat Type Profiles are structural components made from stainless steel with specific shapes. The fluted profile features parallel grooves or ridges along its length, resembling flutes on a column. The hat type profile has a cross-section that resembles the shape of a hat, with a wider top and narrower bottom.

What are the characteristics of Stainless Steel Fluted and Hat Type Profiles?

These profiles are made from durable stainless steel, providing excellent corrosion resistance and structural strength. The fluted design adds texture and visual interest, while the hat type profile offers a unique geometric shape.

Where are Stainless Steel Fluted and Hat Type Profiles commonly used?

These profiles are commonly used in architecture, interior design, furniture manufacturing, decorative accents, and structural applications. They can be used for columns, beams, decorative trim, handrails, and more.

What are the benefits of using Stainless Steel Fluted and Hat Type Profiles?

The benefits include durability, corrosion resistance, aesthetic appeal, versatility in applications, structural support, and the ability to create customized design elements with texture and geometric shapes.

Can Stainless Steel Fluted and Hat Type Profiles be customized?

Yes, these profiles can often be customized in terms of size, length, thickness, and design details to suit specific project requirements. Customizations allow for tailored solutions that match different architectural and design needs.

Are Stainless Steel Fluted and Hat Type Profiles suitable for outdoor use?

Yes, these profiles are suitable for outdoor use when made from stainless steel, which is inherently resistant to corrosion. Proper finishes and coatings can enhance their durability in outdoor environments.

How do you install Stainless Steel Fluted and Hat Type Profiles?

Installation methods may vary depending on the specific application and design of the profiles. They can be installed using welding, adhesives, mechanical fasteners, or other suitable methods based on structural requirements.