Listing ID #5323734

Company Information

Ask for more detail from the seller

Contact Supplier

Technical Features

Typical Industrial Applications

Materials

Performance Capabilities

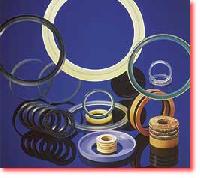

Mak-Tech Seals is an esteemed manufacturing company that has been operating in the field of mechanical shaft seals and seal components from its headquarters in Mumbai (Maharashtra). The company is recognized as a reliable manufacturer, exporter, and supplier of different kinds of Seal Components and O.E.M Pump Seals like Stationary Parts, Conical Spring Seals, Elastomer Bellow Seals, Parallel Spring Seals, Multiple Spring Seals, Wave Spring Seals, Grundfos Pump Seals, Lowara Pump Seals, K.S.B. Pump Seals, Viking Pump Seals, Wilo Pump Seals, Alfa Laval Pump Seals, and Fristam Pump Seals. We manufacture these mechanical shaft seals for various industries like Chemicals, Fertilizers, Textiles, Processing, Solvent, Extractions, Petrochemicals and Thermal Power Plants etc. We have been supplying suitable mechanical seals for centrifugal pumps, compressors, mixers etc., for handling any type of liquid for the media such as chemical fluids, acids, salts, abrasives corrosives, hydrocarbons, crude oils, petroleum products etc.

We can supply mechanical seals for any shaft sizes and speed up to 25000 R.P.M. and for all service. Also, we can supply any mechanical seals of any imported or indigenous make at per or of superior quality. We have also achieved a rare honor of serving various extraction plants and refineries extracting edible oils of different types. We have successfully supplied seals for under Vacuum Pumps, Spray Pumps, Transfer Pumps and Hot Oil Pumps like 15 PCH 75/9, SHD 50/26, 1pce 63 Kilosker Pumps, CHPST Akay Pumps, Khimline 80-250 CPKEY 50/250, KSB Pumps etc. To name a few pumps used in these types of industries.

Mr. Amin Dhaga, who is the Proprietor of the company, laid the foundation stone of Mak-Tech Seals back in the year 1988. Since then the company has been excelling in serving clients with products that conform to the strictest of industrial norms.

Technical Advice

Our engineering department will assess your needs in order to find the best sealing solution for your project. We propose integral advice, from the equipment selection and problem-solving, up to planning and implementation of the project.

Product Range and Stock Availability

MAK-TECH SEALS offers you the most comprehensive range of mechanical seals and gland packing for every common industry. Moreover, we are keen on reducing our delivery time to a maximum so your production never stops.

Quality and Reliability

All of our products are manufactured under the highest standards of quality and certifications, in order to ensure that your company’s demands are met. Our final objective is customer satisfaction.

Product Repair Service

We have developed our own repair service which is available for all our models and applications. Our service includes evaluation, diagnosis, analysis, repairing, manufacturing, and testing.