Listing ID #1524356

Company Information

Ask for more detail from the seller

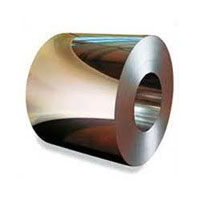

Contact SupplierWe are the noteworthy Manufacturer, Exporter and Supplier of durable SS304-SS304L Stainless Steel Products. Made from high-grade stainless steel, our products are appreciated for high strength, corrosion resistance, heat resistance, excellent finish, etc. We offer these Stainless Steel Products in different specifications to meet the exact application requirements of the buyers. Place bulk as well as urgent orders for Stainless Steel Products with us!

General Properties : Stainless Steel 304 / 304L is a T-300 series stainless steel austenitic, which has a minimum of 18% chromium and 8% nickel. SS304 / 304L has a carbon maximum is 0.030. It is the standard “18/8 stainless” that is commonly found in pans and cooking tools. SS304 / 304Lis the most versatile and widely used alloy in the stainless steel family. Ideal for a wide variety of home and commercial applications, SS304 / 304Lexhibits excellent corrosion resistance and has a high ease of fabrication, outstanding formability. The austenitic stainless steels are also considered to be the most weldable of the high-alloy steels and can be welded by all fusion and resistance welding processes.

Specifications : UNS S30400 / UNS S30403

Applications :

SS304 / 304LStainless Steel is used in a wide variety of home and commercial applications, including :

Standards :

Corrosion Resistance :

Heat Resistance :

Properties of 304 Alloy

Welding Characteristics :

Excellent welding properties; post-weld annealing is not required when welding thin sections. Two important considerations in producing weld joints in the austenitic stainless steels are :

Machinability : The use of chip breakers is advised since the chips can be stringy. Stainless steel work harden rapidly, heavy positive feeds, sharp tooling, and a rigid set-up should be used. of cut below the work-hardened layer resulting from the previous passes.

| Grade | C | Mn | Si | P | S | Cr | Ni | N |

|---|---|---|---|---|---|---|---|---|

| 304 | 0.07max | 2.0max | 0.75max | 0.45max | 0.03max | min - 18.0 max - 20.0 | min - 8.0 max - 10.5 | — |

| Grade | Tensile Strength ksi (min) | Yield Strength 0.2% ksi (min) | Elongation % | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 304 | 75 | 30 | 40 | 201 | 92 |

| Density lbm/in3 | Thermal Conductivity (BTU/h ft. oF) | Electrical Resistivity (in x 10-6) | Modulus of Elasticity (psi x 106 | Coefficient of Thermal Expansion (in/in)/ oF x 10-6 | Specific Heat (BTU/lb/ | Melting Range |

|---|---|---|---|---|---|---|

| at 68oF: 0.285 | 9.4 at 212oF | 28.3 at 68oF | 28 | 9.4 at 32 – 212 oF | 0.1200 at 68oF to 212oF | 2500 to 2590 |

| 12.4 at 932 oF | 39.4 at 7520F | 10.2 at 32 – 1000 oF | ||||

| 49.6 at 1652 oF | 10.4 at 32 – 1500oF |