Listing ID #3878214

Company Information

Ask for more detail from the seller

Contact SupplierA DECADE OF EXPERIENCE

SAKAV, established in 1985, has developed and supplied a wide range of SPRAY DRYING SYSTEMS to the Chemicals, Dyestuffs, Ceramics, Food, Polymers and Pharmaceutical Industries in India and Abroad. With its vast specializes experience, resources and innovative technical know-how, SAKAV offers the most appropriate systems for all Spray Drying requirements designed and delivered by Sakav incorporate practically every conceivable combination of system components to meet a variety of product requirements.

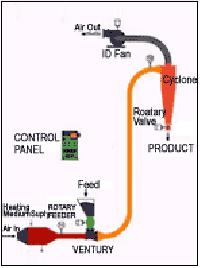

THE SPRAY DRYING OPTIONA spray drying system employs a single process to convert a solution/slurry into a powder.

The liquid is atomized, in a specially designed Drying Chamber, into a stream of hot air to evaporate the solvent. The dry powder is then separated from the air stream. Sakav custom designs a system to suit the product quality, feed conditions, heating source available and the local environment norms.

The chamber geometry, spray pattern and the air flow distribution have a decisive influence on the product characteristics.

Each system is a harmonious combination of individual process sections of Air Heating, Feeding, Atomization, Powder Collection and Dust Separation. The wide variation of combinations handled by SAKAV are given in the table below -

ROTARY ATOMISER

SAKAV with its in-house design capabilities ha built and supplied a range of Rotary Disc Atomizer. These are belt driven units with standard electrical motors. A number of models are available with wheel diameters of 100mm to 350mm and are suitable for capacities from 5 lit/hr to 10,000 lit/hr Various configurations such as orifice, pin, vane with stainless steel and ceramic wear parts are available. A variety of lubrication systems starting from continuous drip to fully automatic forced lubrication systems can be provided. Speed variations are achieved by changed pulleys or variable frequency drivers.

TEST FACILITYFully equipped dedicated Pilot Spray Dryers are available for conducting trials on customers samples and simulation of ideal drying parameters for individual products. Assessment of their physical properties such as moisture content, approximate particle size distribution and bulk density. Testing is an on-going process and SAKAV has, over the years, built-up a large data base for a wide variety of products.

THE CHAMBER OPTIONSThe chamber configuration plays an important part in meeting the end product requirements. As is apparent from the table there is an endless number of possible combination. Some of these have been depicted below.

FLAT ROOFThis is the most widely used configuration of spray chamber with flat roof construction. Co-current swirling air flow pattern is used in conjunction with centrifugal atomization. Generally used for producing a uniform fine powder. Dry powder can be collected partly under the chamber and the fines from the cyclone. Alternatively a single point collection under the cyclone can be provided. Can be adapted for nozzle atomization with an add-on air distributor.

TALL FORM - BUSTLEThe standard Tall Form Bustle construction with co-current linearized air flow pattern is sued with pressure nozzle atomization systems. The dry product is usually coarser than centrifugal disc atomized product. The bustle construction enables separation of coarse fraction below the chamber and the fines can be collected from the cyclone. This configuration is deal where fines recycle is used for product agglomeration.

TWO STAGEA configuration consisting of Tall Form Spray Chamber with a second stage Fluid Bed Dryer is used for special applications. This configuration is used for products requiring longer drying times which cannot be provided in Spray Chamber. This occurs when a coarse product has to be dried to a very low moisture content or when the product to be dried is hygroscopic in nature

| EQUIPMENT | VARIATIONS | ||

| Air Heaters | Fired Heaters | : | Direct : LDO, HSD, Gas |

| Indirect : LDO, HSD, FO LSHS. | |||

| Finned Radiator | : | Steam, Thermic Fluid. | |

| Electrical Heater | : | Bare, Finned | |

| Burners | : | Monoblock Pressure Jet, Low air pressure, | |

| : | High Air Pressure, LPG, CNG. | ||

| : | Air Temperatures from 150%c to 1100%c | ||

| Feed Preparation | Screw Pump | : | Single Multi Stage. |

| Plunger Pump | : | High, Low Pressure, | |

| Hose Diaphragm Pump | : | ----- | |

| Slurry Preparation Equipment | : | Feed Dependent. | |

| Atomizer | Rotary Disc | : | Wheel Dia : 100 mm to 350 mm |

| : | Wheel type : with parts in SS & Ceramic | ||

| Pressure Nozzle | : | Low, High Pressure | |

| Two Fluid Nozzle | : | Air atomizing | |

| Chambers | Flat Roof | ||

| Tall Form | |||

| Tall Form | |||

| Tall Form | |||

| Combination of Nozzle, and Rotary Disc, Single Nozzle, Multi Nozzle Falling Spray, | Co-current, Counter current, Roof Cooling, Fountain Spray. | ||

| Product Separation | Single Point, Two Point or Multi Point | ||

| Cyclone Bag Filter | : | Low/High Pressure Drop Reserve Pulse Jet, | |

| Bag Filter | : | Reserve Pulse Jet, | |

| Self Cleaning | |||

| Wet Scrubber | : | Multi cyclonic, Low pressure drop – ventury, | |

| High pressure drop – ventury, | |||

| Controls | : | DCS, PLC, MICRO-PROCESSOR | |

| Safety | : | Explosion Vents, Pressure Release | |

| Flaps, Fire quenching nozzles. | |||

| Capacities | Feed | : | Clear solutions to slurries with 60% |

| Solid concentration | |||

| Feed Rate | : | 5 lit/hr to 5000 lit/hr | |

| : | Powder, granules | ||

| Material of Construction | : | SS304, SS316, SS316L, SS410, SS310 | |

| Fabrication | : | Shop as well as site fabrication. |