Listing ID #1581681

Company Information

Ask for more detail from the seller

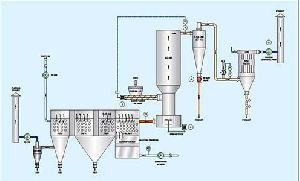

Contact SupplierA spin flash dryer produces powder from feed, which is viscous or gelatinous in nature, paste or filter cake. The two step process involves disintegration of the feed and drying of the disintegrated feed. Depending upon the nature of the feed material, conventional arm design could be used for crystalline, non-sticky material or Acmefil's specially engineered rotating spin design disintegrator could be used to handle sticky and gelatinous materials.

The disintegrated material is brought in contact with the hot drying media, which dries the particle and also pneumatically conveys it for separation in a cyclone or bag filter.

A product clarifier ensures desired size and the dried particles only leave the drying chamber.

High solid contents make the spin flash drier a very economical drying proposition.

Spin flash dryer is a easy process for drying Filter Cakes, Pastes and high Viscous liquid.

Advantages :

Material is directly fed from filter press to dryer.

Less drying time hence less labour handling and quick production.

Less electricity load

Space is 1/3 that of Spray dryer

Various product range.

Energy consumption saving.

Fuel consumption saving.

Influence of heat on heat sensitive products is remarkably low even at high temperature.

Lump breaker with variable speed feed screw feeder for non clogging of feed.

Only two operators are required to operate the plant instead of number of labourers in conventional drying system.

The environmental conditions remains clean.

THE PROCESS :

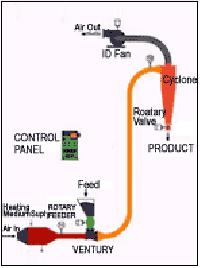

The product is fed to the feed Agitator which is connected to a variable speed screw conveyor and conveyed to the Spin flash chamber in a rated capacity. The air is heated by passing over indirect fired hot air generator. The material come to the spin flash chamber get disintegrated between the rotating spins and simultaneously dried within the hot air media. Dried product is collected from the bottom of bag filter. A separate control panel mounted with instruments is also provided. The process is displayed by MIMIC diagram on control panel.

The material of construction of equipment depends on the product to be dried. The advantage of the system is that it can be operated at high temperature for non sensitive products.