Listing ID #5871590

Company Information

Ask for more detail from the seller

Contact SupplierWhen transferring liquids, delayed flow rates or erratic operation can stall processes and drive an entire day's timetable off-schedule. Lower the downtime and experience the extended hours of stable operation Fluidyne's tanker unloading system can provide.

These systems are extensively used in industries while unloading fuel from tankers as an improvement over traditional dip rod measurement standard. We present a wide range of liquid and solvents loading and unloading systems for preventing the wastage of fuel as well as accurate unloading for audits.

Assembled with positive displacement flowmeters, our systems ensure a high level of accuracy in their measurements. These oil and chemical tanker unloading systems are most suitable for liquid fuels like diesel, petrol, kerosene and other solvents.

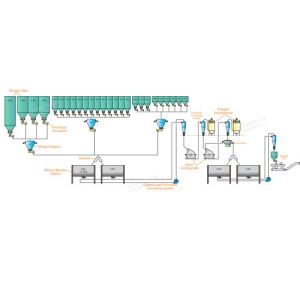

Solvent and chemical batching-Fluidyne

Fluidyne's dispensing and batching systems are flexible and highly dependable. As they come with a small footprint, they are also easy to integrate within existing systems. Our Series 6730 Preset Batching systems can function independently or can be used with existing machines. They completely substitute batch mixing and facilitate on-demand metering, giving a carefully mixed product and decreased waste. Each chemical batching system offers a customized turn-key engineering design, created for specific liquids and designed to handle shifting ratio mixing, varying viscosities, and many other scenarios.

The Configuration of Chemical Batching System:

The Series 6730 Batching System is created for dispensing exact preset quantities of liquids into storage tanks, reactors, batch reactor vessels, etc. With the choice of pneumatically or electrically-activated ON/OFF valves, our weatherproof or flameproof batch controller presents a system ideal for solvent and chemical batching applications with automatic cut-off action coupled with high accuracy.

Benefits:

Application:

The batch process is a manufacturing process that works in short bursts of time, in situations the size or scale of production does not warrant a continuous operation. Nearly all chemical and solvent production is carried out in batches, especially in the food and pharmaceutical industry. The system is also used at plants for batch solvent extraction.

Fluidyne's dispensing and batching systems can be employed for solvent and chemical batching and transferring, including in the production of:

We, Fluidyne Control System (P) Ltd, established our operation in the year 1994 in Pune, Maharashtra, India. We are the leading manufacturer, exporter and supplier of standard liquid filling, Evac and Fill dispensing system and much more. All our products are precisely engineered as per the predefined industry standards. Acclaimed for their operations fluency, robust construction and longer operational life, our product range is massively sought after in pharmaceutical industries.

We have established a state of the art infrastructure that comprises cutting edge technology based machines, equipment and tools and other basic amenities, that help us in carrying out all the operation with ease and perfection. Moreover, the entire range is manufactured by the predefined industry guidelines, to ensure durability and quality.

Furthermore, we have recruited a team of qualified, skilled and experienced professionals, who work in full coordination with each other and work extremely focused and hard to conquer the organisational objectives, with enhanced efficiency. Not only in India but we are famous globally as well. Adding to this we have gained a long list of clients who love our products and services.

Why Us?

We are capable of fulfilling all the needs of our customers and clients. We have magnificent industry experience, vast knowledge of the market and constant guidance from our mentors, which have helped us a lot in planning out strategies for reaching great heights in the business. In future, we wish to garner more customers.

We are the best choice of our customers for our products are affordable and quality assured. Therefore choose us and deal with us to get the best quality products at an affordable price.