Listing ID #3557279

Company Information

Ask for more detail from the seller

Contact Supplier|

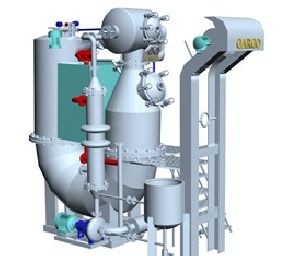

special series connection type twin nozzle : one in front and the other at rear. Help to push and transport fabric. Help to push and transport fabric. Help to increase the number of times saturate and in contact with the fabrics, increase dye quality. |

|

| the delivery tube is design to go downward then turn upward. This will create the push effects to change the position of fabric all the time to avoid the crease mark.

plaiter system : the end of the fabric tube is equipped with plaiter. It can swing left to right to arrange the fabric orderly into the "j box" decrease tangling and fully utilize fabric storage space to increase capacity. during the dyeing process some foam will be build up in the bath and separate from the fabric. This avoids the fabric from flooding and problem of tangling and foam pollution. can be adjusted according to different fabrics. for pure cotton the liquor ratio is 1:5-7. most suitable for high class fabric. advance design concept : only need to adjust the pressure of nozzle and water level. Easy operations even for the beginner. the machine is equipped with advance micro computer controller (we can also fit the machine with different controller if the customer wants to) equipped with auto adding (dye chemical) and manual adding (dye chemical) total surface of the machine goes through "sand-blasting" treatment. special recommendations : this machine has produced super results with all kinds of 100% cotton, viscose rayon,wool,nylon. Acetate : spandex (lycra) |

|

|

ITEM MODEL |

LDMW-1T |

LDMW-2T |

LDMW-3T |

LDMW-4T |

|

NO. OF TUBES |

1 |

2 |

3 |

4 |

| Max.Capacity | ||||

|

KG |

180-230 |

360-460 |

540-700 |

720-930 |

|

LB |

330-396 |

660-792 |

1320-1584 |

1980-2376 |

|

LIQUOR RATIO |

1 : 5 : 7 |

|

|

MAX. WORKING TEMPERATURE |

95° |

|

|

FABRIC SPEED M/MIN |

250 |

|

|

HEATING RATE (MIN) |

10 |

|

|

COOLING RATE (MIN) |

10 |

|

Space Requried (MM) |

||||

|

Min Pump Power |

7.5HP |

10HP |

15HP |

20HP |

|

L1 |

25 35 |

25 35 |

2610 |

2730 |

|

L2 |

3600 |

3600 |

3600 |

3600 |

|

W |

3365 |

4120 |

5815 |

7590 |

|

H |

3320 |

3320 |

3320 |

3320 |