Listing ID #3870141

Company Information

Ask for more detail from the seller

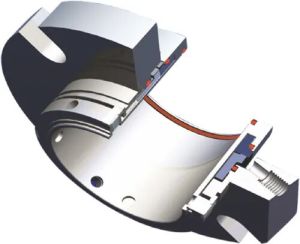

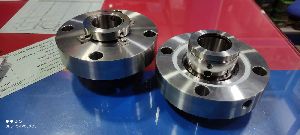

Contact SupplierRotomech single-acting cartridge mechanical seals are complete pre-assembled units ready for insatallation and operation. These cartridge mehanical seals are multiple springs (protected) type, balanced ,independent of direction of rotation, stationary design with long-hole fixing. Cartridge Assembly aids to fix mechanical seal in position ready for installation. These cartridge mechanical seals are designed for technically demanding applications - high degree of capacity for solids. Complete mechanical seal with sleeve and cover with circulation connections (quench optional). Exclusive use of solid seal face/ stationary seat - self-aligning arrangement in stationary design ensures safety of operation and usually increases service life. Mechanical seal is also very suitable with retrofitting of packing; usually fits into packing stuffing box compartments. Mechanical seal fits into DIN space for installation.