Company Information

Ask for more detail from the seller

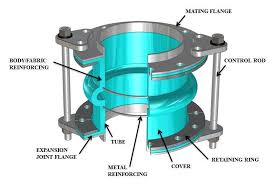

Contact SupplierExpansion joints are often included in industrial piping systems to

accommodate movement due to thermal and mechanical changes in the

system. When the process requires large changes in temperature, metal

components change size. Expansion joints with metal bellows are designed to

accommodate certain movements while minimizing the transfer of forces to

sensitive components in the system.

Pressure created by pumps or gravity is used to move fluids through the piping

system. Fluids under pressure occupy the volume of their container. The

unique concept of PRESSURE BALANCED EXPANSION JOINTS(PBEXJ) is they are

designed to maintain a constant volume by having balancing bellows

compensate for volume changes in the bellows (line bellows) which is moved

by the pipe. An early name for these devices was “pressure-volumetric

compensator”.

Pressure Balanced: Applications

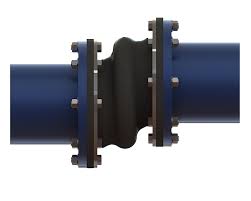

Engineers often specify a pressure balanced expansion joint in the piping

connecting the boiler feed-pump turbine exhaust to the condenser in

conventional fossil-fueled electric power generating plants. [1] Variations in

operating conditions cause frequent changes in temperature, pressure and

steam quality. Condensers are designed to withstand steam generator

overloads without causing significant loss of electric power, but the piping

system must accept the forces associated with these variations.