Listing ID #3800589

Company Information

Ask for more detail from the seller

Contact SupplierProblems that originate from vibrations are frequently encountered in boring and other operations, especially when machining with long overhangs. The vibrations may cause bad surface texture, insufficient accuracy, loss of productivity, increased insert and machine tool wear, as well as noise.

Solving vibration problems will therefore always give you a productivity boost.

Features

ISO application area

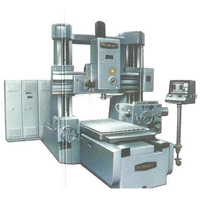

Machine tools and spindle interfaces

Machine tools and spindle interfaces need to be strong and stable to hold large tools and assemblies as CoroBore 826D XL. Suitable interfaces are therefore HSK 100 and Coromant Capto® C8 – C10. ISO 50 taper (BIG PLUS included) is too weak for these roughing tools.

Cutting data

The recommended start values for inserts and grades listed at the box shall be followed, but be aware of the many parameters that have to be taken into consideration – such as actual work piece material, spindle interface clamping force, torque capacity at given RPM, net power etc.